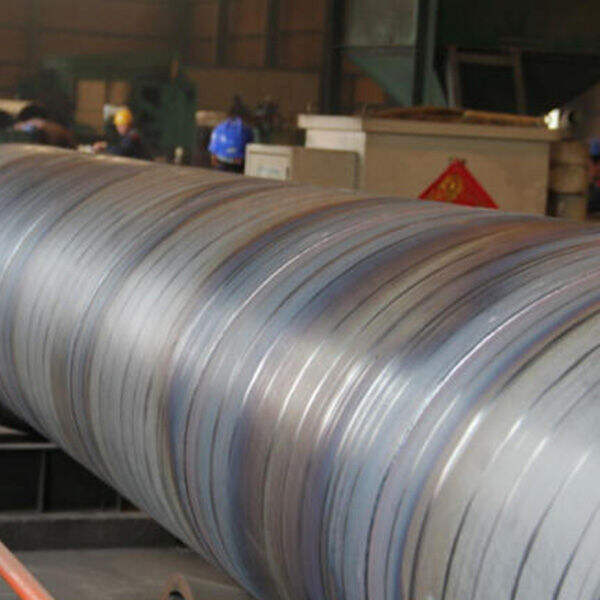

Solche Stahlrohre sind sehr wichtig, um metallene Teile durch Schweißen zu verbinden. Es ist entscheidend, das passende Stahlrohr auszuwählen, wenn Sie bereit sind, ein paar Metallstücke zu verbinden, wofür Rohre benötigt werden. Wenn Sie das falsche auswählen, könnte dies zu einem schwachen Schweiss führen und auseinanderfallen. Dies verursacht Probleme bei Ruijie, wenn Sie mitten in einem Projekt stecken, und diese fliehenden Fäden können sogar gefährlich sein. Diese schraubengeflechtrohr sind nur einige wichtige Dinge, die man wissen sollte, wenn man das richtige Stahlrohr für das Schweißen auswählt.

Stahl: Stahl ist ein starkes Material, das aus Eisen, Kohlenstoff und einigen anderen Spurenelementen besteht. Das macht Stahl zu einem Material der Wahl für viele große Bauprojekte, wie hohe Gebäude, lange Brücken und große Schiffe – keines von denen sein massives Gewicht ohne die durch diese Eigenschaften gebotene Stärke tragen könnte. Im Grunde genommen sind Stahlrohre hohle Röhren, die aus eisengehaltenen und nicht eisengehaltenen Metallen hergestellt werden. Sie können Flüssigkeiten, Gase transportieren oder andere tragende Elemente stützen und halten. Es gibt verschiedene Größen, Formen und Dicken von Stahlrohren auf der Welt. Diese Vielfalt hilft Ihnen, das richtige Rohr für viele Arbeiten zu finden.

Bevor Sie Stahlrohre schweißen möchten, ist es notwendig für uns, die Eigenschaften derselben zu berücksichtigen. Festigkeit - Zugfestigkeit, Zähigkeit sind die wichtigsten Merkmale, die berücksichtigt werden müssen. Festigkeit ist das Gewicht oder der Druck, den Stahl tragen kann, bevor er sich biegt oder bricht. Zugfestigkeit - Stahl kann sich wie Gumby über Meilen strecken, bevor er bricht. Dies ist signifikant, da manchmal beim Gebrauch die Rohre ein wenig gebogen werden müssen. Zähigkeit - Diese misst, wie gut der Stahl darin ist, Risse davon abzuhalten, sich auszubreiten, wenn er beansprucht wird. Das Ruijie-Problem ist, dass jeder dieser Merkmale einen erheblichen Einfluss darauf hat, wie die geschweißten Rohre tatsächlich performen werden.

Folgen Sie diesen grundlegenden Schritten, um sicherzustellen, dass Ihr geschweißtes Stahlrohr stark und zuverlässig ist: Die spiralgeschweißtes Stahlrohr die Oberfläche der Stahlrohre muss gereinigt werden, um jeglichen Schmutz, Rost oder andere Elemente zu entfernen, die eine gute Schweissnaht verhindern könnten. Stellen Sie dann sicher, dass die Rohre senkrecht und waagerecht sind. Denn wenn die Rohre krumm sind, wird dies zu einer schlechten Schweissnaht führen. Anschließend sollten Sie die Röhren sichern, um sicherzustellen, dass sie während des Schweißens nicht bewegt werden. Bewegungen können Fugen und Rahmen beeinträchtigen, was zu Schweßlücken und Brüchen führt.

Denken Sie also an ein paar wichtige Punkte, wenn Sie eine 3PE-Beschichtungsstahlröhre auswählen beste Schweißtechnik für deinen Stahlrohr. Das Erste, was bei Ruijie zu wissen ist, welchen Stahl du hast. Stahl kommt in vielen Varianten, und einige sind schwieriger zu bearbeiten als andere. Edelstahl zum Beispiel muss mit speziellen Geräten und Methoden geschweißt werden, da er sich sehr anders verhält, wenn er erhitzt wird. Zweitens musst du die Dicke der Rohre kennen. Bei dickeren Rohren benötigt es mehr Wärme und tiefergehende Nahtverbindungen, um sie sicher zusammenzufügen. Als Nächstes sprechen wir über die Schweißposition. Je nachdem, wie du schweißt – sei es flach oder vertikal – werden unterschiedliche Fähigkeiten und Verfahren benötigt.

Die Bearbeitungsmethode des Stahlrohres muss aufgrund seiner 3pe Stahlrohr material und Dicke, daher wird Schweißen mit dem Bogen häufig verwendet. Elektrischer Strom erhitzt und schmilzt das Stahl, was eine starke Verbindung herstellt. Durch das Schmelzen des Stahls mit einer Flamme anstatt Licht von außen zu fokussieren, Gas-Schweißen im Vergleich zu Laser-Schweißen, wobei Gas-Schweißen einen offenen Fackelstrahl wie bei Gaza verwendet, der nur für kleine Arbeiten geeignet ist. Andererseits ist Laser ein nicht-kontaktbezogener Typ ohne glühenden Metallpulveranschluss an dieser Stelle, um große Verformungen sicherzustellen, blieben Qualitätprobleme ungelöst. Für die ganze Welt nicht ganz so eng verbunden, aber versuchen wir es noch einmal, können wir Herausforderungen genießen! Beide Methoden haben ihre Vor- und Nachteile, sie erfordern auch spezifische Werkzeuge oder Fähigkeiten, um ordnungsgemäß ausgeführt zu werden.

Es gibt mehrere Vorteile durch den Einsatz hochwertiger Stahlrohre für das Schweißen, und diese können einen großen Unterschied in Ihren Projekten machen. Sie erzeugen eine stärkere Verbindung und erhöhen auch die Haltbarkeit. Dies 3PE-Beschichtungsstahlröhre auswählen denn hochwertige Stähle haben bessere Eigenschaften als Niedrig-Kohlenstoff-Stähle, was sie in der Lage versetzt, im Vergleich viel höhere Belastungen zu tragen. Ein weiterer Grund ist, dass erstklassiger Stahl die Wahrscheinlichkeit bestimmter Probleme oder Ausfallsituationen verringert. Schlechter Stahl kann Einschlüsse und andere Mängel aufweisen, die den Schweißnaht ver schwächen und später Probleme verursachen. Drittens kann ein anständiger Stahl dir Zeit und Geld sparen. Ein hochwertiger Stahl kann erheblich Zeit sparen, sowohl bei der Vorbereitung der Arbeit – für das Schweißen – als auch beim eigentlichen Schweißen. Niederwertige Stähle können dagegen schwächere/falsche Lösungen produzieren, die nicht so lange halten, nachdem du sie abgeschlossen hast.

Wir sind darauf bedacht, die Umwelt zu fördern und zu schützen, in dem Stahlrohrwerk wir betreiben. Stahlrohr für das Schweißen ist entscheidend für unseren langfristigen Erfolg. Wir haben in Technologien und Prozesse investiert, die unsere ökologische Bilanz minimieren und die Energieeffizienz verbessern. Wir arbeiten daran, unsere umweltfreundliche Leistung durch Programme zur Reduktion von Abfällen, Recycling, den Einsatz von energieeffizienteren Maschinen sowie erneuerbaren Energien zu erhöhen. Unsere Verpflichtung gegenüber der Nachhaltigkeit ist nicht nur ein Slogan, sondern ein grundlegendes Prinzip, das jede unserer Entscheidungen leitet, um sicherzustellen, dass wir eine positive Erbschaft für zukünftige Generationen hinterlassen.

Stahlrohr für Schweissen erfreut, dass wir maßgeschneiderte Lösungen für Stahlröhren anbieten. Unser engagiertes Entwicklungs- und Anpassungsteam arbeitet eng mit Kunden zusammen, um deren spezifische Bedürfnisse zu verstehen, sei es die Herstellung eines speziellen Legierungsstoffes für extreme Umgebungen, das Erreichen präziser dimensionsmäßiger Toleranzen oder das Anbringen spezieller Behandlungen auf Oberflächen. Dieser Grad an Personalisierung, kombiniert mit unserer umfangreichen Erfahrung und unserem Wissen über die Branche, ermöglicht es uns, Stahlröhren zu liefern, die genau den spezifischen Anforderungen und Herausforderungen jedes Projekts gerecht werden. So entstehen langfristige Beziehungen und wird die Entwicklung von Technologie auf dem Markt vorangetrieben.

Unsere Stahlröhrenfabrik setzt Qualität an oberste Stelle bei allem, was wir tun. Wir halten uns an die strengsten internationalen Qualitätsstandards und setzen ein effizientes Qualitätsmanagementsystem während des gesamten Produktionsprozesses um. Wir stellen sicher, dass jede Stahlröhre den Erwartungen des Kunden entspricht oder diese sogar übertrifft – von der sorgfältigen Prüfung der Rohstoffe bis hin zu intensiven Tests des Endprodukts und in der Verarbeitung. Stahlröhren sind für ihre Stärke, Haltbarkeit und Stahlrohre zum Schweißen bekannt. Unsere präzise Ingenieurskunst in Kombination mit hochwertigen Materialien, fortschrittlichen Fertigungstechniken und unserem Fokus auf Präzision führt zu Stahlröhren, die für ihre Dauerhaftigkeit, Stärke und dimensionsmäßige Genauigkeit bekannt sind.

Die von uns betriebene Stahlrohrfabrik zeichnet sich durch die neuesten automatisierten Produktionsmethoden aus, die den Fertigungsprozess revolutioniert haben. Durch die Integration von Technologien und Prozessen für Schweisstahlrohre können wir jeden Schritt vom Rohstoffmanagement bis zur Endproduktverpackung optimieren, wodurch manuelle Eingriffe minimiert und die Produktivität maximiert werden. Dieser Grad an Automatisierung gewährleistet konstante und schnelle Produktionszeiten und ermöglicht zudem eine sofortige Überwachung und Anpassung, was die Ressourcenzuweisung optimiert und die Ausfallzeiten reduziert. Somit können wir flexibel auf Marktänderungen reagieren und große Aufträge mit hoher Präzision abwickeln. Dadurch wird eine neue Effizienznorm gesetzt.