This is a task that professional welders can accomplish if they have to knowledge and the right tools for it, but when black iron pipe falls apart! It is a craft that can be used to bind two metal pieces together, enabling them in turn for use various other purposes. These are some of the key points listed above about Ruijie spiral welded steel pipe, and if anyone wants to be a good welder then it could very important for them one these easy steps. Now there are a lot of tips and cues for start working with it step by step. Here are a couple of ideas that sound somewhat useful.

While you are welding black iron pipe, your main aim must be to build a durable join that can cope with an extensive period of use. Thankfully, it's possible to prepare for good welds by taking a specific few steps right now. Absolutely the first, make sure that your welding parts are clean and there was no rust or dirt. Consequently, your welds will not bond properly if the surfaces on which you are welding are dirty — being neat and accurate in every piece of metal that is welded could make all. Then weld this with the right tools/devices. You could need a special welding equipment or correct variety of welding rod to do an excellent work. The equipment serves no useful purpose during the welding process.

Before manufacturing black iron pipe, it is necessary to figure out several indispensable facts. Preparation- The first thing to do is make sure you have everything that this task requires. Of course, not without a welder with the welding rods being used and his industrial mask to cover all breathing-hole parts of his face from noxious fumes & hot coals; plus gloves if you care to keep your hands. Once you have the tools in hand, start to practice your welds (not on your actual project), this will help familiarize yourself with welding and build confidence. Now, steady as she goes. Making sure each weld is a sound one, and rushing may increase potential errors.

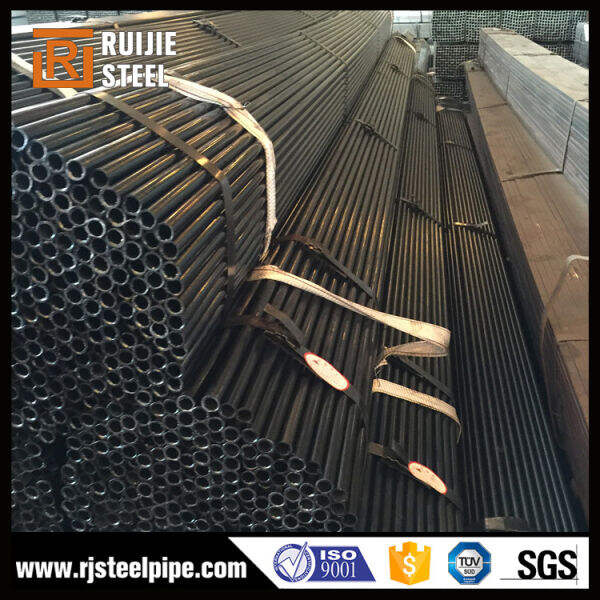

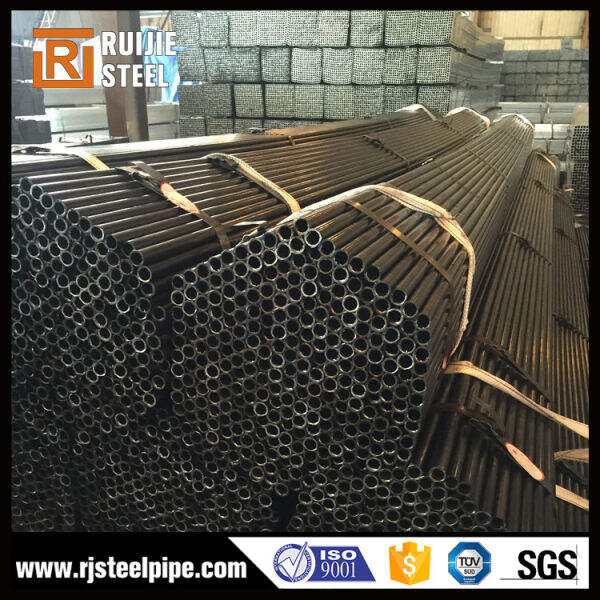

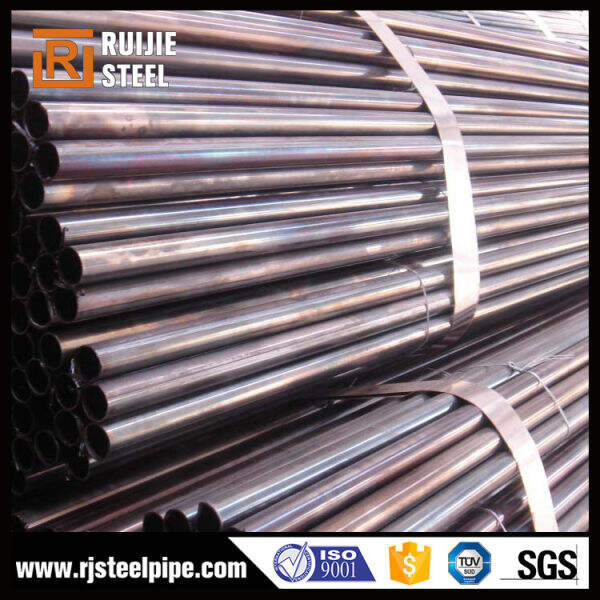

Great pipe for welding- The latter is the Ruijie spiral seam welded pipe and it can work well with various versatile using purposes. Black iron pipe is great, because it can take a hit and its strong. That is why it works perfectly for both fences or handrails and certain furniture. Additionally, black iron pipe is frequently less expensive than other types of metal. That makes it one of the best value buys for anyone who wants to save money, but still have quality materials. Plus, the truth of the matter is black iron pipe could be used for an array of welding applications. It is incredibly versatile, and it is loved by welders everywhere.

Tools and Equipment Required for Welding 1 Inch Black Iron Pipe: To carry out these repairs, you would want a welder in all probability together with some rod of the same fabric kind as well as safety items like gloves or even welders hats to protect yourself from the glare produced by means of an arc. Well, the next necessity to wash in a well-ventilated area. So you will not be inhaling a smoke and fumes that could harm your health. Also, make sure that you have on hard shoes to stop anything from piercing through the soles and do not wear loose clothing as it could easily get trapped in your welding gear. But, of course, you must always be safe and do whatever works best for your situation. A SAFE WORKSPACE!

Albeit, this is mainly for proper welding of black iron pipe; if you really want to be a pro I would suggest picking your local professional welders brains! Or maybe you take a welding class with somewhat arrogant teacher. Or, you can go and get yourself a mentor in order to learn more about it. In addition, you can find unlimited online resources including articles and instructive videos on Ruijie metal pipe welding. But, when utilized they can turn you into a welding master.

We're proud of being able to offer Black iron pipe welding for steel tubes. Our committed rd and customizing team is in close contact with customers to learn about their individual needs in developing a custom alloy for extreme environments, creating precise dimensions, or using special treatment techniques to the surface. Our vast industry experience and knowledge, combined with this degree of personalization lets us deliver steel pipes that precisely match the particular requirements and challenges of every application. This fosters long-term relationships and creates new ideas within the marketplace.

We're dedicated to promoting and protecting the environment in the steel tube manufacturing plant we operate. Black iron pipe welding is vital to our success over the long in the long run. We've invested in technologies and processes which minimize our environmental impact and improve energy efficiency. We work to enhance our environmental performance by creating programs for reducing waste recycling, implementing machines that use less energy as well as renewable energy sources. Our commitment to sustainability is not just a slogan but it is a fundamental principle that guides every decision we make to ensure that we leave a positive legacy to future generations.

Our steel tube factory places quality at the forefront of everything we do. We adhere to strict international quality standards, implementing a comprehensive quality management system that spans the entire manufacturing lifecycle. From a meticulous inspection of raw materials to rigorous in-process and final tests of the finished product we leave no stone unturned in ensuring that every steel tube meets or exceeds the expectations of our customers. Our emphasis on precision engineering, combined with the use and application of high-quality materials and modern manufacturing techniques, results in steel tubes that are known for their strength, durability and precision in dimensional measurements that have earned us a name for delivering Black iron pipe welding.

Our steel tube factory is distinguished by its advanced automated production systems that revolutionize the manufacturing process. By integrating the latest technologies to streamline each procedure from handling raw materials to final product packaging eliminating manual interventions and increasing the efficiency of production. This degree of automation not only assures constant and fast production cycles but also enables immediate monitoring and adjustment to optimize resource allocation, as well as decreasing the amount of Black iron pipe welding. We are able to quickly react to market conditions, and complete massive orders with precision and speed, setting a new benchmark for the efficiency of our industry.