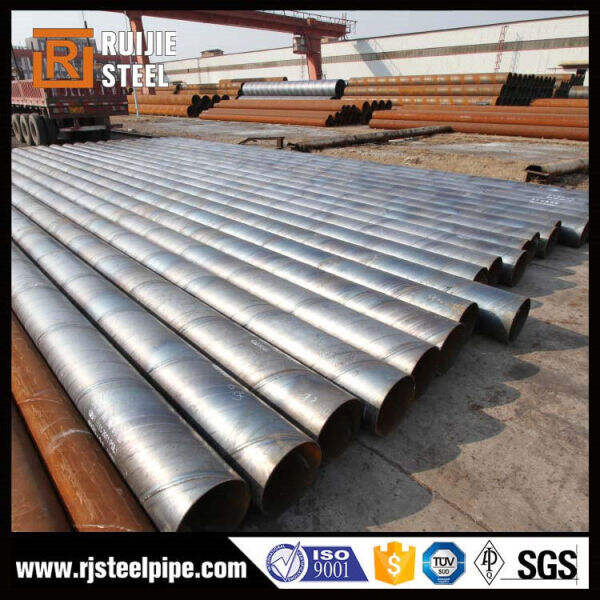

Spiral seam welded pipe is a special type of spiral-weld steel pipes, and its role is to make changes on the pressure pipeline. A spiral wound is a result of integrating the edges of two steel pieces. This Ruijie is the type of pipe that many industries use, but it plays an even larger role in heavy industry. Construction of big elements such as buildings, bridges and power plants that are fundamental for society on a daily basis falls under the category of heavy industry.

Spiral seam welded pipes are also very durable, which is another great benefit. This spiral welded pipe makes it incredibly strong and long lasting, meaning that once you have installed a concrete patio from us; this will be the only one you need for many years to come. In heavy industry, pipes and equipment are costly to replace so this trait is especially desirable. Companies that use durable products like spiral seam welded pipe have fewer expenses.

The Ruijie pipe is welded and fully inspected. Workers also ensure that pipes are up to code and follow all the safety guidelines in their industry. Avoid this due to the fact that it makes sure that the pipe work as intended when it is being made use of. After the inspection, a protective layer is applied to the pipe so that it may be protected from rust and other forms of damage appearing in time.

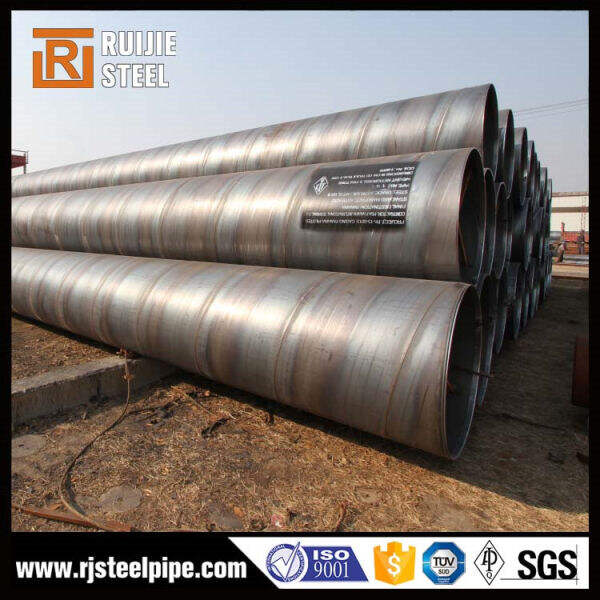

Oil and gasoline pipelines are perfect for using spiral seam welded pipes, due to the fact this spiral steel pipe, pipe is very durable. Crucially, it is designed to maintain pressure and temperature for the transportation of these materials.

Nowadays, spiral in the formation of a power generation plant is widely used for manufacturing Longitudinal pipe; but also very large diameter spiral welded pipe. Spiral seam longitudinal use only to mention that on fluid transports realize important benefits when you work with them. This spiral pipe supplier is a fantastic solution for many different uses due to its strength, reliability and cheaper costs. This Ruijie pipe is utilized to construct bridges, structures used in power plants among other heavy industry applications that must be subjected to heavier loads and tough conditions.

Value of strut-type welding in oil and gas sector. Spiral seam welded pipe is used to transport oil, natural gas from their source to processing facilities. This spiral welded pipe suppliers is an essential means to keep the price of energy lower and more accessible, gaining access to potential oil and gas resources from around the world. If we use this type of pipe, then that way energy production can still be maintained efficiently and economically.

Spiral seam welded pipe is only a category of heavy industry and other large pipes in one effort. There metal spiral pipe are various other kinds of pipes made for different uses and also each with its very own advantages. But recently, we can see a spiral seam welded pipe has importance on building infrastructure. It is also cheap and reliable with considerable strength, which makes it a prime candidate to use in many applications.

Our steel tube factory places quality at the top of everything we do. We adhere to the strictest international standards of quality and employ an efficient management system for quality throughout the production process. We make sure that each steel tube meets or above the customer's expectations, right from the meticulous test of raw materials to rigorous testing of the final product and in-processing. Steel tubes are renowned for their strength, durability and Spiral seam welded pipe. Our precision engineering combined with high-grade materials, advanced manufacturing techniques and our focus on precision engineering result in steel tube that is renowned for its durability, strength and dimensional precision.

Understanding the distinct needs of our customers across various industries, we pride ourselves on the ability to customize Spiral seam welded pipe solutions. Our highly skilled RD and customization team works closely with clients to determine their needs whether it's preparing an alloy that is specifically designed for extreme environments, achieving precise tolerances in dimensional dimensions, or applying special coatings. This level of customization along with our extensive industry knowledge and expertise, enables us to deliver steel tubes that precisely meet the unique challenges and demands of each application, fostering long-term relationships and fostering innovations in the market.

Our steel tube factory is distinguished by its advanced automated production systems that revolutionize the manufacturing process. By integrating the latest technologies to streamline each procedure from handling raw materials to final product packaging eliminating manual interventions and increasing the efficiency of production. This degree of automation not only assures constant and fast production cycles but also enables immediate monitoring and adjustment to optimize resource allocation, as well as decreasing the amount of Spiral seam welded pipe. We are able to quickly react to market conditions, and complete massive orders with precision and speed, setting a new benchmark for the efficiency of our industry.

We're dedicated to promoting and protecting the Spiral seam welded pipe in our facility for manufacturing steel tubes. We are aware that responsible manufacturing is not only beneficial to the planet but also vital to our long-term success. We have therefore invested in processes and technologies which minimize our environmental impact and increase the efficiency of our energy usage. We work to enhance our environmental performance by developing programs for waste reduction recycling, as well as adopting equipment with low energy consumption and renewable sources of energy. Sustainability is more than a word. It's a principle which guides all decisions we take.