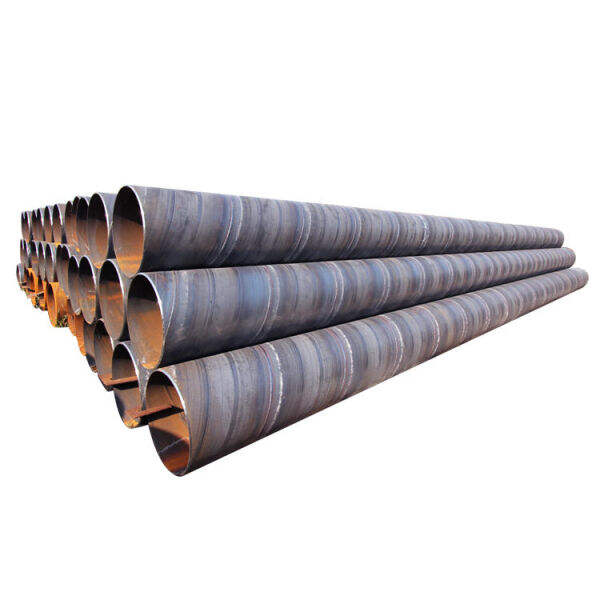

Ever wondered how is a pipe manufactured? The thing we call pipes is important because what fills a pipe usually starts from one place and needs to be carried somewhere else. Spiral welded steel pipe one of the strongest and most commonly used type.

One Piece (Singe-Walled Steel or SWS): This steel drainage pipe is very strong, however this comes at a cost, which limits water flow to 2.5 gallons per second as gravity reduces the internal surface area less accessible due to its thickness and it can handle heavy loads efficiently.

For spiral welded steel pipes, we start from big sheets that cooked for texturing, also the Ruijie's product such as american spiral weld pipe. One side is they begin stripping the steel into long strips. Thereafter these strips are turned in spiral shape. They are molded and then welded together to make a pipe. A unique type of a machine is involved in the movement and placement of steel strips to weld them together. This is necessary, as it will complete the weld accurately and make a tight technical knot between two steel sheets.

When it comes to spiral welded steel pipes, you will find that they can be used in so many places and for the various applications, as well as the spiral weld supplied by Ruijie. You will notice them during works at building site developing robust edifice. They are also used in oil and gas industries where they carry essential equipment. Even in domestic plumbing, these pipes can be found here. Some are available in slim designs suitable for homes; other people will still remain thicker versions meant for factories as well as some various large structures.

The durability is the great feature to consider about using spiral welded steel pipes, identical to Ruijie's product spiral pipe supplier. That means it is incredibly durable. These materials take a lot of force and bend without fault, lasting many years before eventually breaking or needing replacement. This strength is enhanced by their robust welding so you can get a strong, reliable box.

A key characteristic of these pipes would be that they are non-corrosive, the same as spiral welded pipe by Ruijie. This is great as it allows them to be used to transport liquids and gases for long distances without breaking. If the pipes corrode, they will either burst or leak and we do not

It offers spiral welded steel pipes that produced through using cutting-edge technology, a notable advantage, along with Ruijie's product american spiral weld pipe. It means that they are carefully and quickly making the pipes. A great deal of this process is done by machines controlled through computers. They promise that the pipes are fabricated in any sought for size This accuracy is beneficial to ensure that the pipes can fit into different systems and work effectively.

we're Spiral welded steel pipe to be able to provide specific solutions for steel tubes our highly skilled rd and customizing team works closely with customers to learn about their individual needs in developing custom alloys to meet the demands of extreme environments creating precise dimensions or using specialized coatings this degree of personalization along with our extensive understanding of the market and our expertise will allow us to offer steel tubes that are ideally suited to the unique challenges and demands of each project creating long-term partnerships and driving forward the development of technology in the market

Our steel tube factory places quality at the forefront of all we do. We adhere to rigorous international quality standards, implementing the most comprehensive quality management process that Spiral welded steel pipe the entire manufacturing lifecycle. From a meticulous inspection of raw materials to rigorous in-process and tests of the finished product We leave no stone unturned in ensuring that each and every steel tube exceeds or meets customer expectations. Steel tubes are well-known for their strength, durability and dimensional accuracy. Our precision engineering combined with premium materials, the most advanced manufacturing techniques, and a focus on precision engineering yields the steel tube that is famous for its strength, durability and dimensional accurate.

At our steel tube factory, we are deeply committed to the protection of the environment and support sustainable practices. We understand that responsible manufacturing isn't just good for the planet but also essential for our long-term growth. To achieve this we have invested in cutting-edge technology and processes to reduce our carbon footprint and improve efficiency in energy use. From implementing recycling and waste reduction initiatives to using equipment that consumes less energy and renewable energy sources, we constantly strive to increase our environmental efficiency. Our sustainable approach is not only a catchy slogan, but rather it is a fundamental principle that guides every decision we make, ensuring that we Spiral welded steel pipe a positive impression for future generations.

The steel tube plant we operate stands out for its automated production systems that revolutionize manufacturing. We utilize the latest technology to streamline every step starting with the raw materials handling and packaging the final product, reducing Spiral welded steel pipe and maximizing throughput. This degree of automation ensures a consistent and swift production cycles but also enables immediate monitoring and adjustment which optimizes resource allocation and reducing the amount of downtime. We are able, as consequence, to respond quickly to changes in the market and also to complete massive orders with a high degree of precision. This sets new standards for productivity.