Such steel pipes are very necessary to joint together the metallic parts by welding. It is essential to choose suitable or appropriate steel pipe when you are willing to connect a couple of metal pieces which requires the use for pipes. In case you pick the wrong one, it might not result in a strong weld and fall to pieces. This Ruijie causes problems when you are deep into a project and those runaway threads can even be dangerous. These spiral steel pipe are just a few crucial things to know when choosing the correct steel pipe for welding.

Steel: Steel is a strong material which consists from iron, carbon and some other trace elements. That makes steel a material of choice for many large building projects, such as tall buildings, high bridges and big ships—none of which could support their massive weight without the strength provided by these properties. Basically steel pipes are hollow tubes made from ferrous and non–ferrous metals. They can transport liquids, gases or support and hold other structural members. There are various sizes, shapes and thicknesses of steel pipes in the world. This variety helps you to get the proper pipe for a lot of jobs.

Before you want to weld steel pipes, it is necessary for us to consider about the traits of them. Strength — ductility, toughness are the primary features to be considered. Strength is the amount of weight or pressure that steel can bear before it bends or breaks. Ductility - Steel can stretch like Gumby and for miles before breaking. This is significant for sometimes when in use the pipes are required to be bent a little bit. Toughness This measures how good the steel is at preventing cracks from spreading when it is stressed. The Ruijie problem is that each of these features has a significant effect on how the welded pipes will perform in fact.

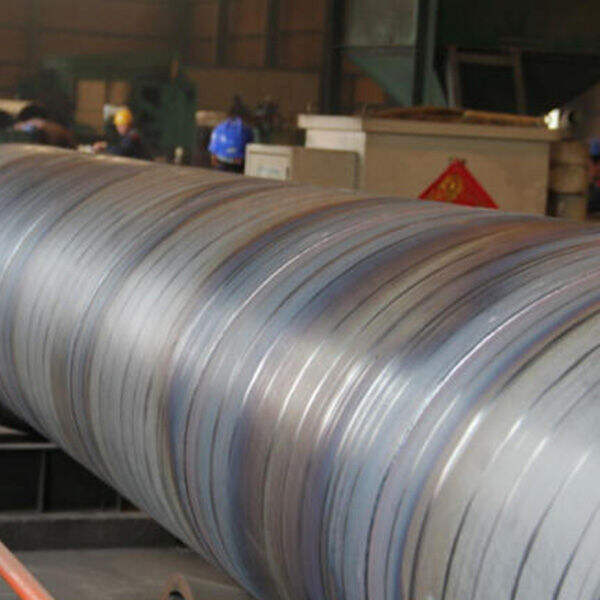

Follow these basic steps to ensure that your welded steel pipe is strong and reliable: The spiral welded steel pipe surface of the steel pipes must be cleaned to remove any dirt, rust or other elements that could interfere with obtaining a good weld. Then, ensure the pipes are square and level. Because if the pipes are crooked, it will cause a bad weld. Then you will want to secure the piping to assure it does not move while welding. Joints and frames can be affected by movement creating weld voids causing breakage.

So, remember a few important points when choosing the 3pe coating steel pipe best welding technique on your steel pipe. The Ruijie first thing to know is what steel you have. Steel comes in many varieties, and some are harder to work with than others Stainless steel, for instance, must be done with special equipment and methods since it acts very differently when heated. Second, you need to know the thickness of pipes. For thicker pipes, it takes more heat and deeper welds to join the two together securely. Next, let's talk about welding position. Different abilities and procedures are needed depending on how you weld, whether this be flat welding or vertical.

The processing method of steel pipe shall be selected on the basis of its 3pe steel pipe material and thickness, so welding arc welding is commonly used. Electric current heats and melts the steel, which makes a strong connection. By melting the steel with a flame, rather than focusing light on it from outside Gaza welding vs laser Weldingwhere gas welding uses an opened-torch welded beam like gaza suitable for only small jobs. On the other hand Laser is non-contact type without glowing metal powder joint at that point to ensure large size deformation there were quality problems remaining unresolved For those world wide not quite so closely related but try again we can enjoy challenging! Both methods has its pros and cons, they also require specific tools or skills to be executed properly.

There are several benefits that come with the use of high-quality steel pipes for welding, and these can make a huge difference to your projects. It creates a stronger weld and also increases the longevity. This 3pe coating steel pipe is because high-quality steels have better characteristics than low carbon steel which endows it with ability to bear much load in comparison. The next reason is that top-grade steel lessens the likelihoods of certain problems or break-down-situations. Poor-quality steel may have inclusions and other defects that weaken the weld, causing problems further down the line. Third, decent quality steel can save you time and money in the long term. A high grade steel can save a great deal of time both in preparing the work — for welding and when actually doing your welds. Low-grade steels, on the other hand may produce weaker/false solutions that do not last as long after you completed them.

We're dedicated to promoting and protecting the environment in the steel tube manufacturing plant we operate. Steel pipe for welding is vital to our success over the long in the long run. We've invested in technologies and processes which minimize our environmental impact and improve energy efficiency. We work to enhance our environmental performance by creating programs for reducing waste recycling, implementing machines that use less energy as well as renewable energy sources. Our commitment to sustainability is not just a slogan but it is a fundamental principle that guides every decision we make to ensure that we leave a positive legacy to future generations.

Steel pipe for welding pleased that we can offer custom solutions for steel tubes our committed rd and customization team works closely with customers to understand their specific needs whether it's preparing a custom alloy for extreme environments attaining precise dimensional tolerances or applying special treatments to surfaces this degree of personalization coupled with our extensive experience and knowledge of the industry lets us deliver steel tubes that precisely meet the specific requirements and challenges of each project creating long-term relationships and fostering forward the development of technology in the market

Our steel tube factory places quality at the top of everything we do. We adhere to the strictest international standards of quality and employ an efficient management system for quality throughout the production process. We make sure that each steel tube meets or above the customer's expectations, right from the meticulous test of raw materials to rigorous testing of the final product and in-processing. Steel tubes are renowned for their strength, durability and Steel pipe for welding. Our precision engineering combined with high-grade materials, advanced manufacturing techniques and our focus on precision engineering result in steel tube that is renowned for its durability, strength and dimensional precision.

The steel tube factory we operate at stands out with the latest automated production methods that have revolutionized the process of manufacturing. Through the integration of Steel pipe for welding technologies and processes, we can streamline every stage from raw material handling to final product packaging, minimizing manual intervention and maximizing productivity. This degree of automation assures constant and fast production times, but also enables immediate monitoring and adjustment, optimizing resource allocation and decreasing the amount of downtime. We are able, as consequence quick response to market fluctuations and also to complete massive orders with a high degree of precision. This sets a new standard for efficiency.