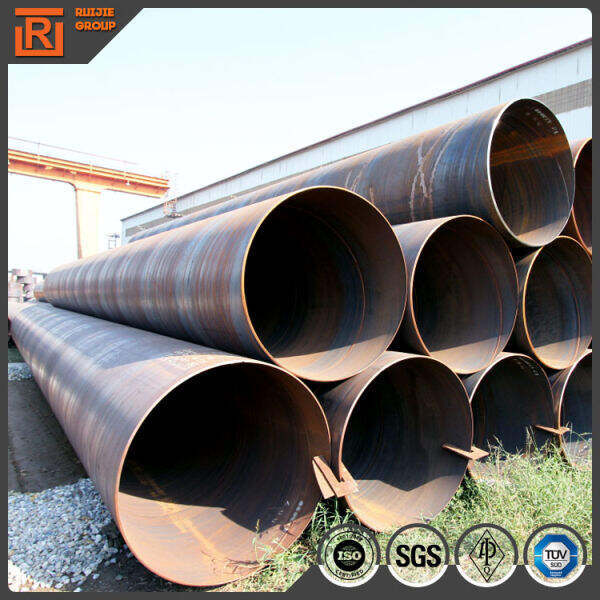

A life without steel pipes for an entire lifetime? The outcome of much more advanced manufacturing expertise compared to our current random house household maintenance guide. These pipes assist in transporting essential substances such as water, gas, and even oil from one location to another. Were you aware of the 3pe coating available for steel pipes? Let's discuss the advantages of using this coating, how it minimizes damage on steel pipes, its composition, its primary uses, and the reasons why individuals in need of steel pipes should choose coated ones. In this part, our focus is on gaining an understanding of 3pe coating. 3PE involves adding three layers of polyethylene to thicken it, creating a special type of thermoset plastic coating for steel pipes. This Ruijie FBE Coating Steel Pipe with coating consists of three separate layers. The first layer is composed of epoxy, the second layer of adhesive, and the final layer is polyethylene. They both offer a strong protective barrier for the steel pipes.

You may be curious about why someone would use 3pe coating on steel pipes. There are actually many advantages to using this type of coating, with the main benefit being its ability to prevent corrosion. Corrosion occurs when metal begins to decay and develop rust as a result of being exposed to the environment, including water and air. This anti-corrosion coating serves as a protective barrier to keep steel dry and prevent rust from developing due to water, chemicals, or microbes that tend to accumulate on its surface over time. 3pe coating provides an additional benefit by enhancing the pipes and increasing the longevity of lightweight materials. Ruijie 3LPE Coating Steel Pipe have a much longer lifespan, so they require fewer replacements or repairs. Additionally, the coating is resistant to scratches and bumps caused by the movement or installation of pipes. This increased durability is quite beneficial in ensuring the longevity of the pipes for many years.

After explaining the concept of CWC and FBE, let's now delve into how the 3pe coating works on steel pipes for external pipeline protection. The engineered process involves heating the Ruijie Epoxy Coal Tar Coating Steel Pipe and spraying on the coating at a specific temperature. Initially, an epoxy layer is applied, followed by the adhesive coat and then a final poly-ethylene layer.

The typical uses of 3PE coating are on steel pipes mentioned in the heading. An example that is often observed in the oil and gas industry is the use of "but". Ruijie Products is crucial to transport oil and gas safely from one location to another here. Moreover, in the water sector for providing safe drinking water to households and commercial establishments.

Moreover, its components are frequently utilized in building projects with 3pe coating. High-quality steel pipes of one inch are essential for various applications where they need to be strong to offer structural support. This layer ensures that the Ruijie 3pe coating last longer and need less maintenance, which is crucial for the success of any construction project.

Quality is at the heart of everything we do in our factory for steel tubes. We adhere to the strictest international standards for quality, and have implemented a comprehensive quality management system which spans the entire production lifecycle. We make sure that every steel tube is up to or even exceeds the customer's expectations, right from the meticulous tests of the raw material to strict in-processing and final product tests. Steel tubes are known for their durability, strength and dimensional accuracy. Our precise engineering paired with high-quality materials, sophisticated manufacturing techniques and our emphasis on precision engineering yields the steel tube that is famous for its strength, durability as well as its dimensional 3pe coating steel pipe.

We're 3pe coating steel pipe to encouraging and protecting the environment in the steel tube manufacturing plant we operate. Responsible manufacturing is the key to our success in the long in the long run. In this regard, we've invested in the most cutting-edge technologies and processes that minimize the environmental impact of our operations and increase energy efficiency. We strive to increase our environmental performance through creating programs for reducing waste recycling, as well as adopting devices that consume less energy and renewable sources of energy. Sustainability goes beyond a slogan. It's a concept which guides all decisions we take.

We're pleased of being able to offer custom solutions for steel tubes. Our rd team and the customization team works closely with our customers in order to fully understand the particular requirements of each customer whether it's 3pe coating steel pipe an individual alloy specifically designed for extreme environments, attaining exact dimensional tolerances or applying specialized surfaces treatments. This level of customization, coupled with our extensive understanding of the market and our expertise, enables us to deliver steel tubes that meet the unique challenges and demands of each use, enabling long-term relationships and fostering forward the development of technology in the market.

The steel tube factory we operate at is distinguished by its cutting-edge automated production systems that transform the process of manufacturing. By integrating the latest technologies to streamline each procedure from handling raw materials to final product packaging minimising manual intervention and increasing throughput. This level of automation not only assures constant and fast production cycles but also enables continuous monitoring and adjustments to optimize resource allocation, as well as reduces the time it takes to complete. In the end, we can swiftly react to market volatility, completing large-scale orders with accuracy and speed. This sets an example for efficiency in the 3pe coating steel pipe.