But I bet you also have experienced what is typical for a factory. Audio of this loud noise comes from large machines that are at hard station. Most factories use steam-or-gas-powered equipment. All of these engines have to transfer gas from one place to another, and hence industries need help of special tubes that are made out of stainless steel.

So however, what exactly are stainless steel pipes? Stainless steel is, in fact, an impressively robust metal. It is pretty magical! For instance, it is not easy to break or rust When workers have to install pipes made out of stainless steel, they can assemble them by welding. Pipes are connected by welding which is the heating up of both edges and sticking them together, in this way they will grow into being strong as ever.

Let’s think about an example. Just think of it as a pipeline for oil from one place to another. That Ruijie pipe has to be strong enough too, because it's where the oil literally flows at a pressure behind. If the pipe is weak, and unable to handle the pressure that could cause it to break causing massive destruction or even hazardous circumstances. Thus stainless steel pipes are the best choice in factories where high pressure pipeline is required.

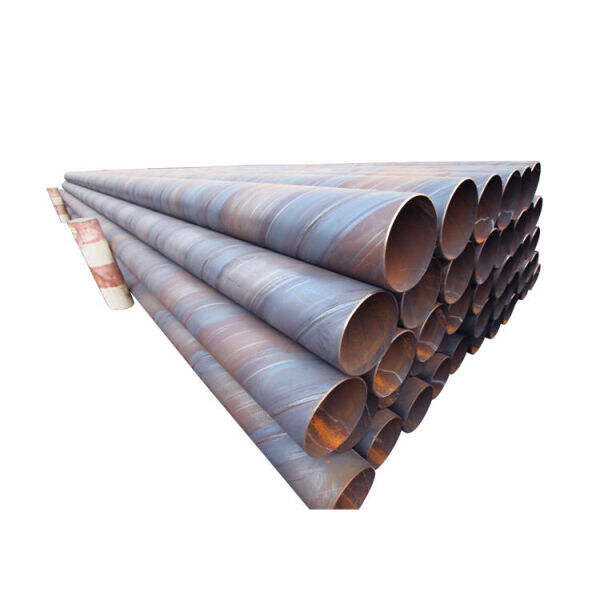

However, if there is no requirement for a seamless pipe in a project then welded pipes are generally the better option. Three subsequent processes known are made to help make these, and pipe the rather less expensive than seamless pipes however equally robust and reliable. In fact, some even think it is easier to repair a leak in welded pipes and so they remain among the top preference.

Rusty pipe, anyone? Which can also be a bad viewing experience and often dangerous as well. Metal corrodes over time, weakening it, and in some cases rust can break down metal — making things fade faster than you would expect. This Ruijie spiral welded pipe is why stainless steel pipes are a great solution to this problem because they do not allow the retaining of dust or moisture on their surface and will be preserved as new if cleaned from time-to-time!

It is resistant to corrosion, highly durable and does not easily corrode away over time. Stainless steel pipes can be a good option for one of these scenarios (building something outside in the elements), such as when you are building a bridge or constructing water treatment facilities. This Ruijie spiral welded pipe suppliers will help guarantee that the structure lasts long, without requiring an overhaul or full replacement.

Specialized welding processes using state-of-the-art technology. These ms spiral welded pipes are techniques for precision welding of ultra-high-strength steels, making the weld seam extremely strong and at least as accurate. It is commonly used in applications where the weld quality must be of a high standard as found in industries like aerospace and automotive.

Our steel tube factory is distinguished by modern production techniques that Ss welded pipes manufacturing processes. We incorporate the latest technologies to automate every step from raw materials handling to packaging products for final production, while reducing any manual intervention, and increasing the efficiency of. This level of automation assures not only consistent and rapid production cycles and monitoring in real-time. It optimizes resource allocation and reduces time to repair. As consequence quick response to market changes and also to complete huge orders with accuracy. This sets a new standard for productivity.

Quality is at the center of all we do at our factory for steel tubes. We adhere to rigorous international standards for quality, and have implemented a comprehensive quality management system which spans the Ss welded pipes. From a meticulous inspection of raw materials to stringent in-process and final product testing we do everything we can in making sure that every steel tube meets or exceeds the expectations of our clients. Steel tubes are known for their durability, strength and dimensional accuracy. Our precision engineering combined with high-grade materials, advanced manufacturing techniques and our emphasis on precision engineering yields steel tube that is renowned for its durability, strength and dimensional accuracy.

At our steel tube plant We are Ss welded pipes committed to protecting the environment and promoting sustainable practices. Responsible manufacturing is essential to our growth in the long term. To achieve this we've invested in the most cutting-edge technology and processes that minimize our carbon footprint and improve energy efficiency. We work to enhance our environmental performance by developing programs for waste reduction recycling, as well as adopting equipment with low energy consumption and renewable sources of energy. Our commitment to sustainability is not only a catchy slogan, but rather it is a fundamental principle that guides each decision we take and ensures that we leave a positive legacy to future generations.

We're pleased of being able to offer custom solutions for steel tubes. Our rd team and the customization team works closely with our customers in order to fully understand the particular requirements of each customer whether it's Ss welded pipes an individual alloy specifically designed for extreme environments, attaining exact dimensional tolerances or applying specialized surfaces treatments. This level of customization, coupled with our extensive understanding of the market and our expertise, enables us to deliver steel tubes that meet the unique challenges and demands of each use, enabling long-term relationships and fostering forward the development of technology in the market.