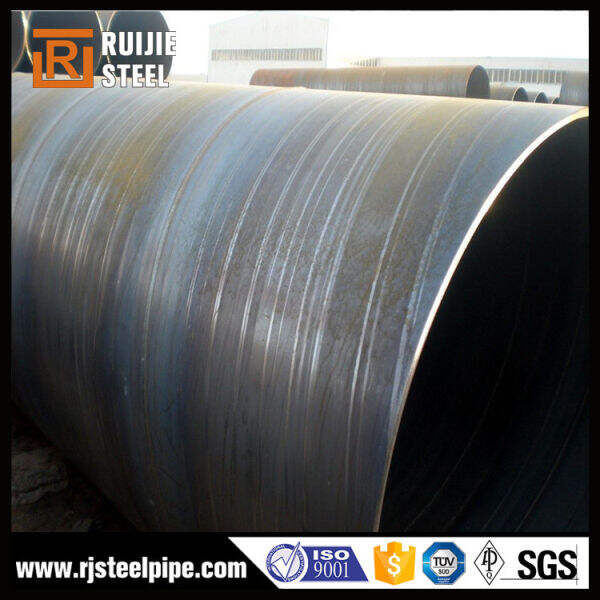

Virkelig stærke tårne til, når bygherrer bygger høje bygninger, store huse, alt skal kunne holde sådan at intet falder sammen. For at gøre dette, anvender de specielle rør, der hjælper med at forbrænde en grund (fundament), hvorpå bygningen vil blive opført. Disse kaldes pipe piles, og de kan være ekstremt små eller brede i diameter; tyndvandede eller tykkervandede; lange med flere led eller korte. Den gennemsnitlige størrelse af Ruijie pipe pile vil være omkring 16 tommer i diameter (for de mindste kan det gå ned til op til 6 tommer) og med vægge, der kan nå op til omkring to tommer.

Der findes flere vigtige punkter, som byggere skal overveje, mens de vælger den rigtige rørpilestørrelse. For det første kigger de på bygningens vægt. Jo højere eller massivere en struktur, der bliver bygget - lejerne, der bor i lejligheder mange etager oppe fra arbejde, tager dusj hver morgen i forskellige rum på bestemte etager (skrub-a-dub), alt sammen over 1 mile højst bedst har større rør. Jorden, hvorpå bygningen er konstrueret, kommer næste. Sammensætning: Struktur - Disse jordarter kan måske ikke holde tungt materiale, (lyder som et større kanal) og de tager højde for om området får storme, orkaner eller jordskælv! Ikke kun det, men det skal også matche størrelsen med Ruijie pipe pile dimensioner eller tinget kan ryste jorden, når disse naturlige begivenheder finder sted.

Grunden er meget sandsynligvis en del af et bygning, fordi alt ovenfor afhænger af den til støtte. En bygning kan ikke eksistere uden at placere disse store rør - rørpiller - i grundfjeldet; faktisk kunne man argumentere for, at det hele er baseret lige på dem. For hvis en forkert størrelse af rørpiller bruges til den bestemte fundament, så kan dette bestemte fundament muligvis ikke være stærkt nok til at holde disse problemer, hvis de dukker op i fremtiden. Det blev også brugt for at få den nødvendige længde af rørpiller og hvor langt de skulle placeres inde i jorden for korrekt at opføre dette bestemte fundament. Dette er for at sikre, at din bygning vil være i god stand og vare mange år, så længe du ønsker det.

Forskellige radius på rørstolper for at opfylde specifikke bygninger. Den fulde udvalg indeholder forskellige størrelser og 4,5 (OD). Det er ligesom et mindre rørstolpe til huset eller gigantiske til skyskraper. Byggere bruger forskellige størrelser af rørstolper for at afgøre, hvilken der vil passe godt ind i hver bygning, da den vil justere sig efter en grundlæggsanmodning. Det er ligesom at vælge det rigtige værktøj til jobbet - størrelsen gør forskel!

Derfor er de bedste størrelser fra Ruijie stål rør pile kan anvendes, når byggere behandler grundlagne for at give dem nok styrke. Men så sikrer de, at rørene er korrekte med hensyn til størrelse og vægt fra 1968, som understøttes af et rør. Tidligere kunne ingeniører, der designer bygninger, også bruge software, der er specielt designet til dem for at hjælpe med at træffe bedre beslutninger om rørstapler. Software kan beregne, hvilke størrelser der vil fungere bedst under test og simulationsoperation.

Vi er stolte af at tilbyde tilpassede løsninger for stål rør. Vores højst kvalificerede forskning og udvikling og Pipe pile dimensioneringsafdeling arbejder tæt sammen med kunder for at få viden om deres individuelle behov, uanset om det er at forberede en tilpasset alloy til ekstreme miljøer, skabe præcise tolerancer i dimensionelle dimensioner eller anvende særlige overfladebehandlinger. Dette niveau af tilpasning kombineret med vores vaste branchekendskab og ekspertise giver os mulighed for at levere stål rør, der præcist møder de specifikke krav og behov for hver enkelt anvendelse, hvilket fremmer varig samarbejde og driver teknologiens udvikling i markedet.

Vi er på Pile dimensioner for at fremme og beskytte miljøet i den stålrokkefabrik, vi driftser. Ansvarlig produktion er nøglen til vores succes på lang sigt. I denne henseende har vi investeret i de mest avancerede teknologier og processer, der mindsker miljøpåvirkningen af vores aktiviteter og forbedrer energieffektiviteten. Vi agter at forbedre vores miljømæssige ydeevne ved at oprette programmer til reduktion af affald, genbrug og ved at indføre apparater, der forbruger mindre energi og anvender fornyelige energikilder. Bæredygtighed går ud over et slogan. Det er et princip, der leder alle vores beslutninger.

Vores fabrik for stålrejser sætter kvalitet øverst på alt, hvad vi gør. Vi følger de strengeste internationale kvalitetsstandarder og anvender et effektivt kvalitetsforvaltningsystem igennem hele produktionen. Vi sikrer, at hver eneste stålrejs opfylder eller overstiger kundens forventninger, fra den omhyggelige test af råmaterialer til den strenge test af det færdige produkt og under-behandling. Stålrejser er kendt for deres styrke, holdbarhed og rørpiledimensioner. Vores nøjagtighedsingeniørarbejde kombineret med højklasse materialer, avancerede fremstillingsmetoder og vores fokus på præcisionsingeniørarbejde resulterer i stålrejser, der er kendt for deres holdbarhed, styrke og dimensionelt nøjagtighed.

Vores fabrik for stålrejser karakteriseres ved dens avancerede automatiserede produktionsanlæg, der revolutionerer fremstillingsprocessen. Ved at integrere de nyeste teknologier for at optimere hver enkelt procedure fra håndtering af råmaterialer til pakning af færdige produkter, elimineres manuel indgriben og produktionseffektiviteten øges. Dette niveau af automatisering sikrer ikke kun konstante og hurtige produceringscykluser, men gør også det muligt at overvåge og justere straks for at optimere ressourcfordelingen og reducere mængden af rejsedimensioner. Vi kan hurtigt reagere på markedsvilkår og udføre store ordrer med præcision og hastighed, hvilket sætter nye standarder for effektivitet i vores branche.