When you think of buildings or bridges, concrete slabs bricks and other wooden materials come to the mind. While these are pretty standard materials, steel is something that even buildings can be made out of. Welded steel tubes are one of the most valuable types of steel in construction. These tubes are rigid and serve for many functions, making the structures safe and robust.

Welded steel tubes are intrinsically weaker than extruded aluminium regardless of shape, also the Ruijie's product such as spiral pipe supplier. This welding technique is important as it offers you a very strong product. These tubes are versatile and can be used for many reasons including buildings, bridges as well as furniture. This is the reason they are chosen for applications in which strength, durability or both are needed.

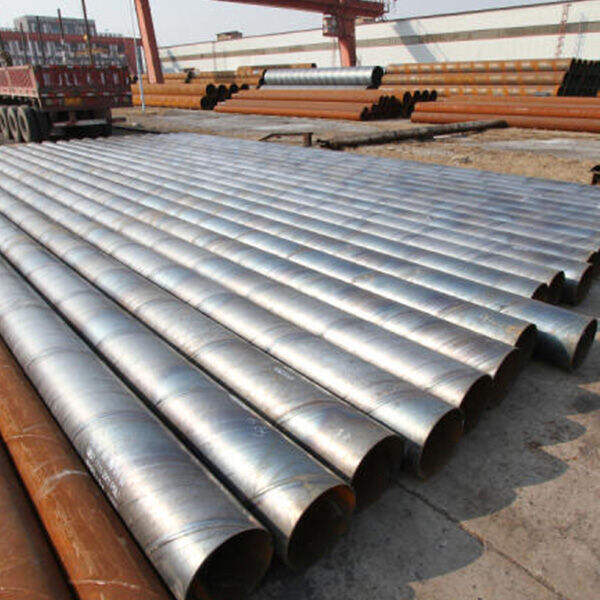

There are several applications of welded steel tubes in construction, as well as the spiral saw pipes supplied by Ruijie. They can, for instance be applied to build the frame of a building or bridge—basically the skeleton that represents its shape and gives it this structural support. They can also help a building hold up walls, roofs and other significant parts. This means they are responsible for ensuring that the buildings and bridges we use on a daily basis, remain safe and sturdy.

Welded steel tube: One of the top things about welded metal tubes is their exceptional strength. They can handle a large amount of weight and will not buckle under pressure, so are ideal for constructing tall buildings or structures that support heavy loads. This kind of strength is especially coveted in heavy traffic areas like stadiums or large office buildings.

Welded Steel Tubes Also Good Weather Resistant This means that they are very capable to deal with the rain, wind and other weathering effects on them, also the Ruijie's product such as steel pipe for welding. This is especially vital for exterior residential as well as business buildings and also bridges that have to sustain whatever nature has in store. They also prevent these structures from deteriorating because they are able to resist tough weather conditions, in order for the structures can be safe and stable when people try sneak into them.

It has a highly skilled skill to get it strong and lope like that, identical to steel pipe for welding by Ruijie. These are trained individuals who will be using a variety of tools and techniques ensure their weld is as strong as possible. They have to meticulously get, for simply a little lack of knowledge can result in complications down the road. Hence their professional presence is crucial for the construction work, as it ensures that buildings and bridges are built to last.

Application of Welded Steel Tubes

Metal wire and the baskets made by it. Since they can handle huge amounts of weight and withstanding demanding situations, this gives you a safe choice for these vital vehicles, similar to the Ruijie's product like spiral welded pipe suppliers. These vehicles will carry either passengers (in the case of passenger cars and buses) or cargo, likely but not exclusively at highway speeds - There are strong frames beneath most if them protecting bankers and bakers alike from sudden snaps.

Understanding the distinct needs of our customers across various industries, we pride ourselves on the ability to customize Welded steel tube solutions. Our highly skilled RD and customization team works closely with clients to determine their needs whether it's preparing an alloy that is specifically designed for extreme environments, achieving precise tolerances in dimensional dimensions, or applying special coatings. This level of customization along with our extensive industry knowledge and expertise, enables us to deliver steel tubes that precisely meet the unique challenges and demands of each application, fostering long-term relationships and fostering innovations in the market.

Quality is at the heart of everything we do in our factory for steel tubes. We adhere to the strictest international standards for quality, and have implemented a comprehensive quality management system which spans the entire production lifecycle. We make sure that every steel tube is up to or even exceeds the customer's expectations, right from the meticulous tests of the raw material to strict in-processing and final product tests. Steel tubes are known for their durability, strength and dimensional accuracy. Our precise engineering paired with high-quality materials, sophisticated manufacturing techniques and our emphasis on precision engineering yields the steel tube that is famous for its strength, durability as well as its dimensional Welded steel tube.

We're dedicated to promoting and protecting the environment in the steel tube manufacturing plant we operate. Welded steel tube is vital to our success over the long in the long run. We've invested in technologies and processes which minimize our environmental impact and improve energy efficiency. We work to enhance our environmental performance by creating programs for reducing waste recycling, implementing machines that use less energy as well as renewable energy sources. Our commitment to sustainability is not just a slogan but it is a fundamental principle that guides every decision we make to ensure that we leave a positive legacy to future generations.

The steel tube plant we operate stands out for its automated production systems that revolutionize manufacturing. We utilize the latest technology to streamline every step starting with the raw materials handling and packaging the final product, reducing Welded steel tube and maximizing throughput. This degree of automation ensures a consistent and swift production cycles but also enables immediate monitoring and adjustment which optimizes resource allocation and reducing the amount of downtime. We are able, as consequence, to respond quickly to changes in the market and also to complete massive orders with a high degree of precision. This sets new standards for productivity.