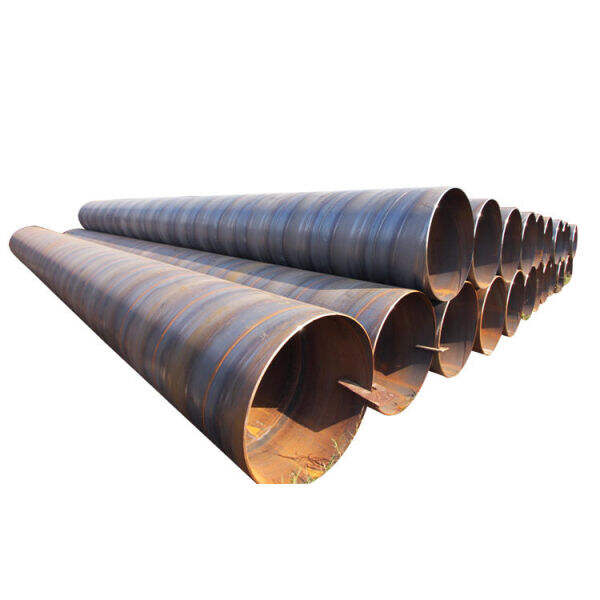

When it comes to a multitude of different jobs and tasks, stainless steel welded pipes are incredibly useful. The best part is that they have so many good features than other materials. These pipes are one of the strongest and longest-lasting pipelines there is. This makes them far less prone breaking and able to withstand a lot of usage. Plus, they do not rust at all, which is key. So due to these properties, Ruijie spiral welded pipe are used in varieties of areas and industries.

There are many different jobs in various industries the SS Welded Pipes can be used for. An example of this is the oil and gas industry, where they work in getting substances. They are also found in chemical process plants. These pipes are essential for plumbing and heating system during the construction. And due to the fact that they do not rust, Ruijie spiral welded pipe can also be used for outdoor buildings and structures (so lasts longer in different weather conditions).

It is also very important to take good care of SS welded pipes. Regular servicing helps in their longer life. This would ultimately mean cleaning Ruijie spiral welded pipe suppliers and removing any kind of dirt or debris that can sit on the surface. It also requires that they be observed regularly for any cracks or splits which could become issues down the line. Inspections at predetermined intervals work in favor of maintaining pipes well.

There are the few important factors that you need to consider when it comes to selecting Ruijie spiral welded pipe suppliers for your requirements. Material is one of the primary variables. Various stainless steels have various characteristics and strengths, so it is important that you select the frequency type to your job.

The pipe size is another thing that you should look into. This will partly be determined by what the Ruijie spiral welded steel pipe is going to be used for, and how much space there has on where it can stay. You must also account for how hot the pipe will get, how much pressure it needs to handle if any as well as include any other specific requirements of the job.

The steel tube plant we operate stands out for its automated production systems that revolutionize manufacturing. We utilize the latest technology to streamline every step starting with the raw materials handling and packaging the final product, reducing Ss welded pipe and maximizing throughput. This degree of automation ensures a consistent and swift production cycles but also enables immediate monitoring and adjustment which optimizes resource allocation and reducing the amount of downtime. We are able, as consequence, to respond quickly to changes in the market and also to complete massive orders with a high degree of precision. This sets new standards for productivity.

We're pleased of being able to offer custom solutions for steel tubes. Our rd team and the customization team works closely with our customers in order to fully understand the particular requirements of each customer whether it's Ss welded pipe an individual alloy specifically designed for extreme environments, attaining exact dimensional tolerances or applying specialized surfaces treatments. This level of customization, coupled with our extensive understanding of the market and our expertise, enables us to deliver steel tubes that meet the unique challenges and demands of each use, enabling long-term relationships and fostering forward the development of technology in the market.

Our factory for Ss welded pipe puts high-quality at the forefront of all we do. We adhere to rigorous international quality standards, implementing a comprehensive quality management system that spans the entire production lifecycle. We ensure that every steel tube is up to or even surpasses our customers' requirements, from precise quality control of raw materials through rigorous manufacturing and testing. Steel tubes are known for their durability, strength and dimensional precision. Our precision engineering combined with high-grade materials, advanced manufacturing techniques and a focus on precision engineering results in steel tube that is renowned for its strength, durability and dimensional accuracy.

At our steel tube factory We are committed to protecting the environment as well as support Ss welded pipe. Responsible manufacturing is crucial to our growth in the long in the long run. In this regard we have invested in cutting-edge technology and processes to reduce the impact on our environment and boost efficiency in energy use. We aim to improve our environmental performance by developing programs for waste reduction recycling, and adopting equipment with low energy consumption and energy sources that are renewable. Our commitment to sustainability is not simply a slogan, but it is a fundamental principle that guides each decision we take to ensure that we leave a positive legacy for future generations.