Are you aware of the spiral weld? You can use this to make pipes for lots of different things. That is exactly what we are going understand in this article: What the Ruijie american spiral weld pipe process is and why it matters when building pipelines, typically used to transport liquids or gases over long distances.

Constructing pipe lines must be robust as possible when it comes to strength. The same informant says that when it comes to pipe lines, the goal is for them "to last forever and under all conditions", such as heavy pressure or different types of weather (rain, snow and heat from sun). It can fracture or crack a pipe that is not strong enough to endure, creating all sorts of problems.

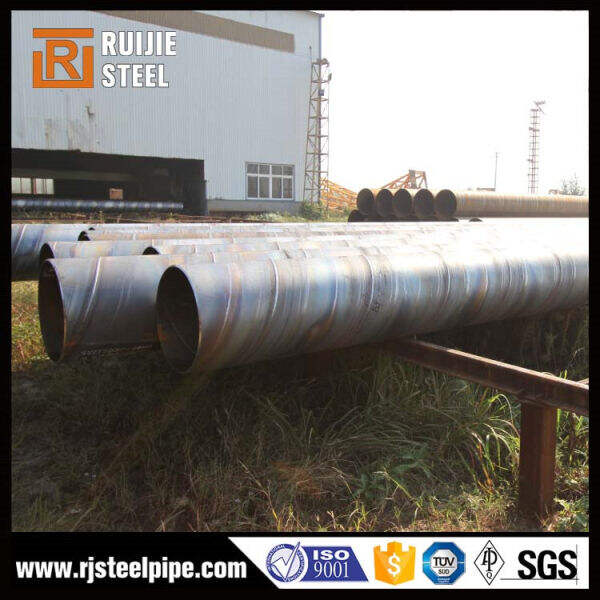

This is where the spiral weld comes in. It forms a spiral seam in the form of a pipe that is longer and stronger than defect free submerged arc welded pipes. There is a special spiral shape with the welded pipes which made it long-lasting, trustful and efficient so that people can easily use them at their place of work.

Spiral weld, then how does it work? The line where the metal is joined in a typical welded pipe runs straight up and down through the length of the pipe. On the other hand, in a Ruijie spiral welded pipe, the seam goes round and round on the steel with exactly one pitch like a kind of spring or curly tape.

It is this special unique shape that gives spiral welded pipes their high strength and durability. Helps them to survive the harsh conditions they are going through. Further, because the Ruijie spiral welded pipe are built in a spiral fashion it reduces the amount of welding that is done compared to traditional manufacturing.

Therefore, the production ratio of spiral welded pipe is higher than that of straight seam welding line. Some are quite sturdy and long-lasting too, so you will not have to concern yourself with shedding the resilience. The combination of strength and low cost makes spiral welded tubes an ideal solution for many companies.

In addition to being stronger, they are also lighter and often cost less to produce. That is why many companies opt for spiral welded pipes instead of buying other types which are too costly but still succeed to build a strong and trustworthy pipeline. The type of T-Joint Welded Steel Pipe used has a large impact on the success (or failure) of your project.

The steel tube Spiral weld we operate at is unique due to modern production techniques that have revolutionized manufacturing processes. By integrating the latest technologies and processes, we can streamline every step from raw material handling to final product packaging minimising manual intervention and increasing the efficiency of production. This level of automation guarantees not only consistent and rapid manufacturing cycles as well as real-time monitoring. It maximizes resource allocation and minimizes the amount of downtime. In the end, we can quickly respond to market fluctuations, fulfilling large-scale orders with precision and speed, setting an example for productivity in the industry.

Our steel tube factory places quality at the Spiral weld of everything we do. We adhere to stringent international quality standards and implement an effective management system for quality throughout the production cycle. We ensure that each steel tube is up to or even surpasses our customers' requirements, from precise tests of the raw material to strict processing and final testing. The focus we place on engineering precision and the use and application of high-quality materials and the most advanced manufacturing techniques, produces steel tubes that are known for their strength, durability and dimensional accuracy which has earned us a reputation for delivering unparalleled quality.

At our Spiral weld We are firmly committed to the protection of the environment and support sustainable methods of production. We understand that responsible manufacturing is not just beneficial for the planet but is essential to our long-term success. We've therefore invested in processes and technologies which minimize our environmental impact and increase efficiency with energy. We are striving to enhance our environmental performance by developing programs for waste reduction recycling, as well as adopting technology that is low-energy as well as renewable energy sources. Sustainability is more than just a slogan. It's a fundamental principle which guides all decisions we take.

Understanding the distinct needs of our customers across various industries, we pride ourselves on the ability to customize steel tube Spiral weld. Our highly skilled rd and customization team works closely with clients to determine their needs whether it's preparing an alloy that is specifically designed for extreme environments, achieving precise tolerances in dimensional dimensions, or applying special coatings. This level of customization along with our extensive industry knowledge and expertise, enables us to deliver steel tubes that precisely meet the unique challenges and demands of each application, fostering long-term relationships and fostering innovations in the market.