If you will use steel pipes for your project, you should understand ASTM A252 very well. But what actually is ASTM A252? So, let’s dive in to learn a bit more about it!

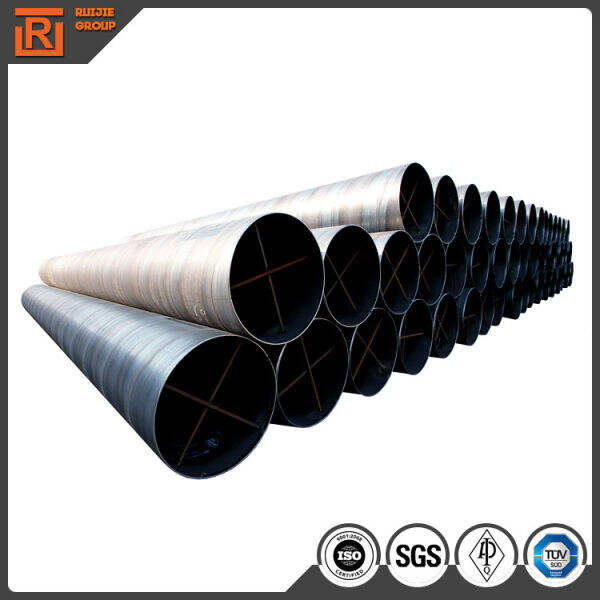

ASTM A252 is a standard specification for welded and seamless steel pipes. Such pipes are indeed also special as they are intended for piling. Piling is the term used for driving large poles deep into the earth. These massive poles are important because they help undergird heavy buildings, long bridges, and other kinds of structures. Many structures would be neither safe nor stable without poles of these great strengths.

There are various reasons ASTM A252 comes in handy. Some of the most common reasons are that these steel pipes can be used in several works. All this means that using ASTM A252 pipes, you can build homes, create bridges, and develop large commercial buildings. ASTM A252 steel pipes and pipe piles are excellent choices whether you are building a small pipe bridge or deploying a water treatment plant. They are highly customizable which have made them well liked by builders and engineers alike.

Benefits of Using ASTM A252 For Construction Projects Top of All, This Standard Pipes Products Are Highly Durable They are able to support a significant amount of weight and can easily withstand heavy pressure. It means, it will be safe for your buildings and structures that you get ASTM A252 pipes. Also these kinds of pipes are quite simple to manufacture and install. While this may be very important for any project, the ease can save time and money during construction.

Some key factors to keep in mind when dealing with ASTM A252 pipes. So now you just have to decide: the right size, or diameter, of the pipes. The thickness of the walls of the tubes are also matters to contemplate. This is important because the larger and thicker they are, the stronger and more durable the pipes will be. If the pipes are too thin, they may not withstand the pressure. In addition to that, you’ll have to make sure you’re using an appropriate type of weld for the pipes. The type of weld you need to perform depends on your specific materials and project requirements.

How ASTM A252 pipes work and their properties are also very crucial things to know. It will also guide you about the best applications for each of the pipes, and how they should be installed. Examples of important properties are yield strength, which explains how much weight a pipe can withstand before it begins to flex, and tensile strength, which shows the force a pipe can withstand before it breaks. Familiarity with these properties will assist you in selecting the proper tubing for your project and guarantee that they will work safely.

We are proud to offer customized solutions for steel tubes. Our highly skilled rd and Astm a252 works closely with clients to learn about their individual needs whether it's preparing a custom alloy for extreme environments, creating precise tolerances in dimensional dimensions, or applying particular surface treatments. This level of customization combined with our vast industry knowledge and expertise allows us to provide steel tubes that precisely meet the particular requirements and needs of every application, encouraging lasting partnerships and driving the pace of forward the development of technology in the market.

The steel tube plant we operate stands out for its automated production systems that revolutionize manufacturing. We utilize the latest technology to streamline every step starting with the raw materials handling and packaging the final product, reducing Astm a252 and maximizing throughput. This degree of automation ensures a consistent and swift production cycles but also enables immediate monitoring and adjustment which optimizes resource allocation and reducing the amount of downtime. We are able, as consequence, to respond quickly to changes in the market and also to complete massive orders with a high degree of precision. This sets new standards for productivity.

Astm a252 our steel tube plant We are dedicated to preserving the environment and promote sustainable methods of production. Responsible manufacturing is vital to our success in the long in the long run. In order to achieve this we have invested in cutting-edge technologies and processes to reduce our carbon footprint and improve efficiency in energy use. We work to increase our environmental performance through creating programs for reducing waste recycling, implementing machines that use less energy as well as renewable energy sources. Sustainability is more than just a word. It's a principle that informs every decision we take.

Quality is the foundation of everything we do at our factory for steel tubes. We adhere to Astm a252 for quality, and have implemented an effective quality management system which spans the entire production lifecycle. From meticulous raw material inspection to stringent in-process and final test of the product We leave no stone unturned in making sure that every steel tube meets or exceeds the expectations of our customers. Our focus on precision engineering, combined with the use of premium materials and advanced manufacturing techniques, produces steel tubes that are recognized for their strength, durability, and dimensional accuracy and has earned us a reputation as a top-quality supplier.