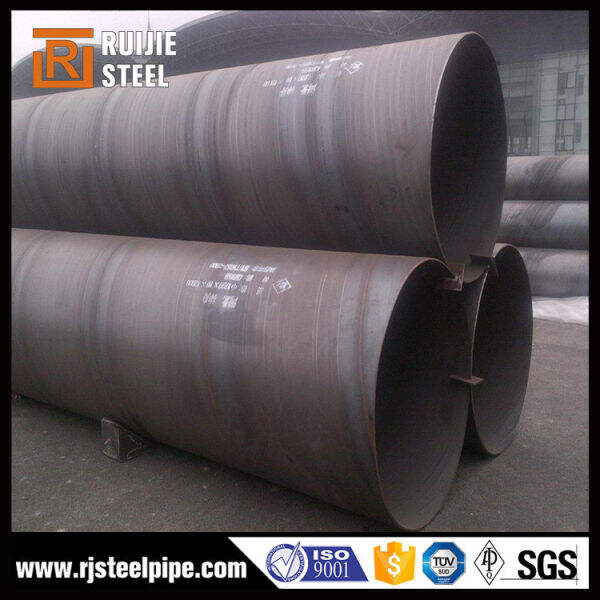

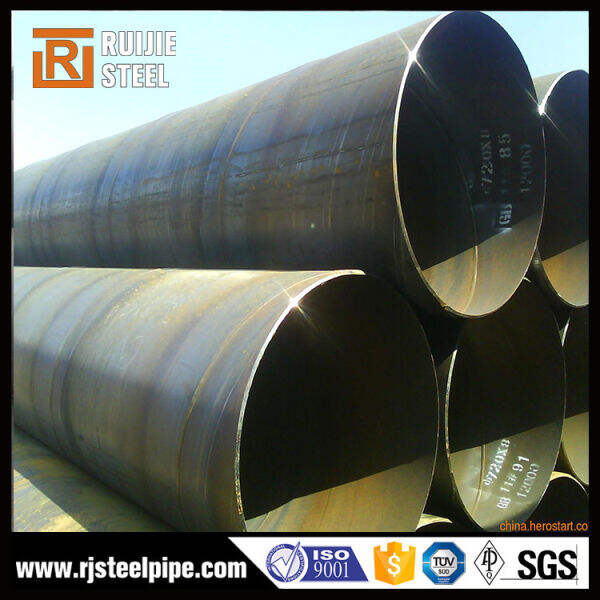

ASTM A53 pipe is a particular kind of nonmetallic tubing used for various applications in industry. Strong steel — so it is very sturdy and will last quite a long time. This means that it is able to resist a large amount of rough use and stay perfectly fine for many years too. ASTM A53 is a set of rules or standards that manufacturers follow. ASTM- This abbreviation represents the American Society for Testing and Materials, an agency that sets standards in terms of what materials should be made up to achieve their purpose safety. One of the biggest benefits regarding Pipe ASTM A53 is due to american spiral weld pipe strength. Well, it is a pipe that can take more pressure hence less chances of cracking and breaking. This is what makes it a go-to option for use-cases across the board. By the way, other than Plumbers Pipe ASTM A53 can also be used in many areas such as construction work etc. Is also NoT that difficult to confirm as well installed & maintained, another If even Easier.

But, there are some setbacks to using Pipe ASTM A53. The major concern is that it may be costlier than other types of pipes. If youare on a budget, then this might be something to think about. Moreover, Pipe ASTM A53 can be a little difficult to work with, particularly if you are going to cut or weld it. It is, in fact, a really tough material but not entirely rust-proof and corrosion-free. It is therefore not suitable for environments that are privately wet or corrosive. So, when you are choosing the Pipe ASTM A53 for your project or application then american spiral weld pipe is very crucial that what exactly do you need Because of this, you need to consider that it is going to take an adequate amount of weight unless predicting fluids or gases passing under pressure and if the tubing may rust over time. By considering these things then only you could get results better.

Essentially, the Process of Pipe ASTM A53 Welded is "Welding". The process consists of heating the metal to a certain very high temperature so that it anti corrosion pipe gets hot enough for us to melt another piece into this one. Most importantly, it is important to adhere to the installation directions since that proper installment will help you have a safer and better working pipe. Once installed correctly, the pipe is sturdy and reliable.

After you have installed the pipe, it is essential to maintain it so that metal pipe welding there are no problems related to its functioning. The maintenance includes washing the pipe in order to get rid of any mud or dust that may clog up over a period. One more important thing is to inspect gears for any damage or rust on a regular basis If you encounter any issues, its best to fix it as quickly as possible to safe-guard against potential future problems.

ASTM A53 pips is a material used in many pruning applications, such as plumbing, heating and cooling systems, construction or transportation. This makes it particularly useful for places that under a heavy amount of pressure or stress, as the ceramic can endure these circumstances without splintering and fragmentation. That astm a312 makes it a favourite solution for lots of different industries and projects.

Pipe astm a53 pleased that we can offer custom solutions for steel tubes our committed rd and customization team works closely with customers to understand their specific needs whether it's preparing a custom alloy for extreme environments attaining precise dimensional tolerances or applying special treatments to surfaces this degree of personalization coupled with our extensive experience and knowledge of the industry lets us deliver steel tubes that precisely meet the specific requirements and challenges of each project creating long-term relationships and fostering forward the development of technology in the market

At our Pipe astm a53 We are firmly committed to the protection of the environment and support sustainable methods of production. We understand that responsible manufacturing is not just beneficial for the planet but is essential to our long-term success. We've therefore invested in processes and technologies which minimize our environmental impact and increase efficiency with energy. We are striving to enhance our environmental performance by developing programs for waste reduction recycling, as well as adopting technology that is low-energy as well as renewable energy sources. Sustainability is more than just a slogan. It's a fundamental principle which guides all decisions we take.

The steel tube Pipe astm a53 we operate at is unique due to modern production techniques that have revolutionized manufacturing processes. By integrating the latest technologies and processes, we can streamline every step from raw material handling to final product packaging minimising manual intervention and increasing the efficiency of production. This level of automation guarantees not only consistent and rapid manufacturing cycles as well as real-time monitoring. It maximizes resource allocation and minimizes the amount of downtime. In the end, we can quickly respond to market fluctuations, fulfilling large-scale orders with precision and speed, setting an example for productivity in the industry.

Quality is the foundation of everything we do at our factory for steel tubes. We adhere to Pipe astm a53 for quality, and have implemented an effective quality management system which spans the entire production lifecycle. From meticulous raw material inspection to stringent in-process and final test of the product We leave no stone unturned in making sure that every steel tube meets or exceeds the expectations of our customers. Our focus on precision engineering, combined with the use of premium materials and advanced manufacturing techniques, produces steel tubes that are recognized for their strength, durability, and dimensional accuracy and has earned us a reputation as a top-quality supplier.