A pile driver is a special way that you can create strong foundations for things like buildings, bridges, and oil-rigs at sea. To pile the pipe, we can only drill holes in the ground or on the seabed under water. After these are dug out, they cover them with a combination of cement and steel pipes. These tubes serve as massive pillars to which everything built upon them depends. Ruijie spiral metal pipe also strengthens structures so you know they will be strong for years to come.

Properly piling pipe together is necessary to maintain the safety and stability of construction projects. The proper piling will have to be done, otherwise there can just be serious issues. If the piles are not strong enough, a building might sink into the ground or lean to one side and potentially be destroyed entirely. It is very hazardous to anyone in the area of a building and also expensive. Workers have to follow rules and practices for piling pipe in the best way possible, which will prevent these kinds of issues even on land. They do this so that things get built right, and to last.

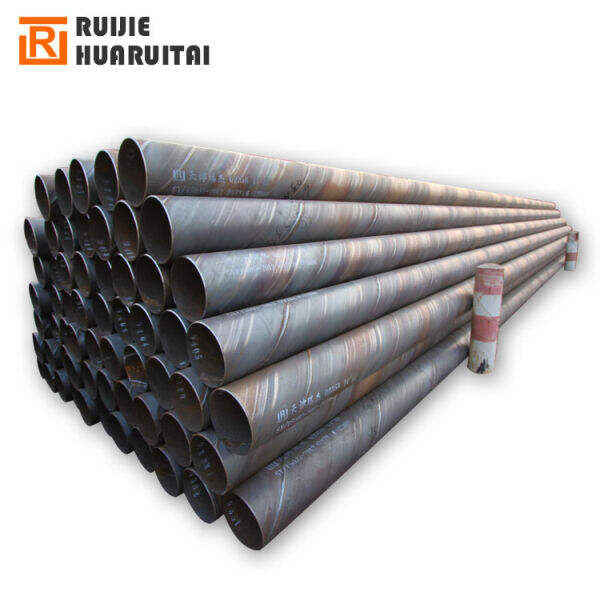

For instance, when workers pile pipe on land each element of the ground needs to be checked very best. They want to be sure the world around them can carry weight without shattering or collapsing. This is accomplished by drilling a test hole and checking the soil to determine whether it will bear the building that is going up there. Once they have loosened up the soil, drill some holes with neat tools that can penetrate extremely deep down — quite often over 100 feet! Next, they employ a mighty contraption called a pile driver to force the Ruijie steel spiral pipe into these holes. That machine just whacks the pipes to ensure a tight fit, like hammering a nail through wood.

Water filling pipe is a little bit more complicated in water then pulling pipe on land. They load the equipment and supplies onto boats designed for special marine construction. Workers then use machines to bury the pipes underneath thousands of meters of ocean sediment. Water is a difficult place to work as it has strong currents and there are number of other hazards, waves etc. Such water movements also make it more difficult to place the right pipes in the right locations, so workers must be very careful that everything is put where they are needed.

Pile pipes have numerous advantages in construction. This base ensures that heavy construction works and fixtures can be supported over it without any damage. Piling pipe, for instance, is useful to prevent erosion ie., when the soil gets washed away with water. Moreover, piling pipes can also be beneficial in constructing the retaining walls. These walls are very effective when it comes to avoiding landslides and flooding. Piling pipe is used in many of the pieces you might find on or below a construction site, and having strong secure pile being driven into the ground to support your project can make all the difference.

One mistake that occur during the piling pipe process is without checking of ground or sea bed at first. If workers take shortcuts and don't complete this essential step properly, then they can compromise the foundations support, with potentially disastrous consequences later on. Your selection of materials and tools must be top shelf as well. Adhering to the right ways of piling Ruijie pile tube secures a triumph. Yet another mistake: Failure to preserve the piling system. Over time if the pipes and foundation begin to suffer, it will cost a good sum of money in fixing problems that could have been prevented.

We're Piling pipe to encouraging and protecting the environment in the steel tube manufacturing plant we operate. Responsible manufacturing is the key to our success in the long in the long run. In this regard, we've invested in the most cutting-edge technologies and processes that minimize the environmental impact of our operations and increase energy efficiency. We strive to increase our environmental performance through creating programs for reducing waste recycling, as well as adopting devices that consume less energy and renewable sources of energy. Sustainability goes beyond a slogan. It's a concept which guides all decisions we take.

The steel tube factory we operate at is distinguished by its cutting-edge automated production systems that transform the process of manufacturing. By integrating the latest technologies to streamline each procedure from handling raw materials to final product packaging minimising manual intervention and increasing throughput. This level of automation not only assures constant and fast production cycles but also enables continuous monitoring and adjustments to optimize resource allocation, as well as reduces the time it takes to complete. In the end, we can swiftly react to market volatility, completing large-scale orders with accuracy and speed. This sets an example for efficiency in the Piling pipe.

Quality is the foundation of everything we do at our factory for steel tubes. We adhere to Piling pipe for quality, and have implemented an effective quality management system which spans the entire production lifecycle. From meticulous raw material inspection to stringent in-process and final test of the product We leave no stone unturned in making sure that every steel tube meets or exceeds the expectations of our customers. Our focus on precision engineering, combined with the use of premium materials and advanced manufacturing techniques, produces steel tubes that are recognized for their strength, durability, and dimensional accuracy and has earned us a reputation as a top-quality supplier.

We're pleased of being able to offer custom solutions for steel tubes. Our rd team and the customization team works closely with our customers in order to fully understand the particular requirements of each customer whether it's Piling pipe an individual alloy specifically designed for extreme environments, attaining exact dimensional tolerances or applying specialized surfaces treatments. This level of customization, coupled with our extensive understanding of the market and our expertise, enables us to deliver steel tubes that meet the unique challenges and demands of each use, enabling long-term relationships and fostering forward the development of technology in the market.