Seamless Carbon Steel Pipe is very important for Many industries Since these pipes are manufactured style of entire tube, there is no joints and weak parts available. This makes it very resilient and reliable. These tubes need an important standard we know its ASTM a106.

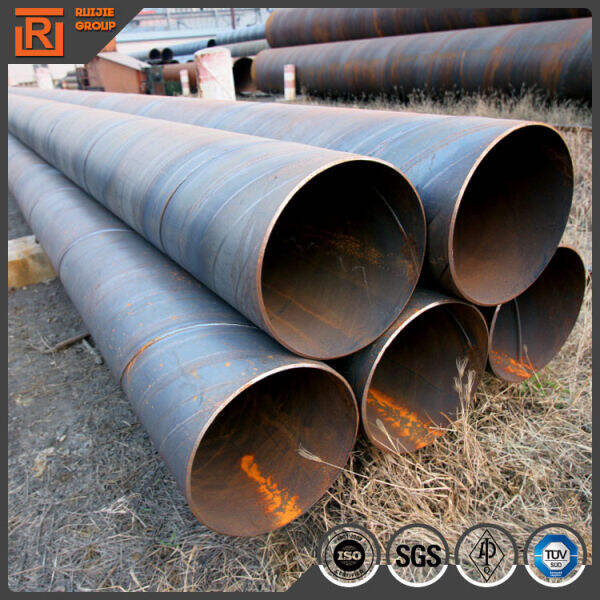

It is a special class of tube which has no welded joint and it also called seamless carbon steel pipe. With this, the Ruijie boriya pola karbonê is actually without weak spots that could break open. These pipes are made by heating a round steel rod until the material is malleable. Large, specially made dies so the steel is forced through to create shape while it's soft. It helps in giving the pipe a desired shape of steel. The result is a strong, yet flexible compound that can withstand heavy stress.

Seamless carbon steel pipes find many applications in several industries such as oil and gas, construction and power generation as these fields need a kind of pipeline that can stand high pressure and withstand extreme heat thus allowing it to transfer harsh substances under the strenuous environment. These are best suited to get this purpose since this Ruijie erw boriyeke pola karbonê can be created tough and durable. Hence, deformation is off the list and hence are robust sufficient to be used for a protracted time even in tough places.

Carbon Seamless Steel Pipes — Carbon steel is very easy to weld and has a wide range of uses, which makes it the first choice for building materials with high towers. This is the very reason that makes them unbeatable for such tasks their strength and reliability. Plus, Ruijie boriyên karbon pola erw are also used in long haul gas or oil pipeline. They are typically transported under high pressure and together with the design of these pipelines.

Where SA 106 is very common so in the oil and gas industry to be used for pipes that called Hydro Fours using quads call API QUAD5 L where this mid gives more protection and strengths to stand at high temperature surround environment. API 5L, the latter is often applied due to pipes being weldable and is in particular suited for transporting various material as tubes one place to another; Certainly, both of these standards are valuable within its features but complementary role also varies according to necessity.

Similarly, the seamless carbon steel pipes also play a very pivotal part in green buildings. These buildings are also very eco-friendly and energy efficient. These buildings have heating-insert and radiant-cool surfaces which, in most cases rely on the use of seamless carbon steel pipes.

At our Astm a106 We are firmly committed to the protection of the environment and support sustainable methods of production. We understand that responsible manufacturing is not just beneficial for the planet but is essential to our long-term success. We've therefore invested in processes and technologies which minimize our environmental impact and increase efficiency with energy. We are striving to enhance our environmental performance by developing programs for waste reduction recycling, as well as adopting technology that is low-energy as well as renewable energy sources. Sustainability is more than just a slogan. It's a fundamental principle which guides all decisions we take.

Our steel tube factory is distinguished by modern production techniques that Astm a106 manufacturing processes. We incorporate the latest technologies to automate every step from raw materials handling to packaging products for final production, while reducing any manual intervention, and increasing the efficiency of. This level of automation assures not only consistent and rapid production cycles and monitoring in real-time. It optimizes resource allocation and reduces time to repair. As consequence quick response to market changes and also to complete huge orders with accuracy. This sets a new standard for productivity.

We're proud of being able to offer Astm a106 for steel tubes. Our committed rd and customizing team is in close contact with customers to learn about their individual needs in developing a custom alloy for extreme environments, creating precise dimensions, or using special treatment techniques to the surface. Our vast industry experience and knowledge, combined with this degree of personalization lets us deliver steel pipes that precisely match the particular requirements and challenges of every application. This fosters long-term relationships and creates new ideas within the marketplace.

Our steel tube factory places quality at the forefront of all we do. We adhere to rigorous international quality standards, implementing the most comprehensive quality management process that Astm a106 the entire manufacturing lifecycle. From a meticulous inspection of raw materials to rigorous in-process and tests of the finished product We leave no stone unturned in ensuring that each and every steel tube exceeds or meets customer expectations. Steel tubes are well-known for their strength, durability and dimensional accuracy. Our precision engineering combined with premium materials, the most advanced manufacturing techniques, and a focus on precision engineering yields the steel tube that is famous for its strength, durability and dimensional accurate.