The Importance of SSAW Spiral Steel Pipes for Australian Mining Sites

Australia is a country with rich metal mineral resources, home to some of the world top mining companies. Given that these minerals serve the economy, their extraction and processing demand reliable infrastructure accurate high-speed technologies to ensure both economic efficiency and personnel safety. Of these advancements, the use of SSAW (Submerged Arc Welded) spiral steel pipes has become more and more widespread in how mining proceeds across the terrain. This article will delve into the integral role that these pipes are playing to improve resource extraction, extend infrastructure longevity, endure extreme conditions and revolutionize mining in Australia.

Where SSAW Spiral Steel Pipes Are Key in Mining Australia

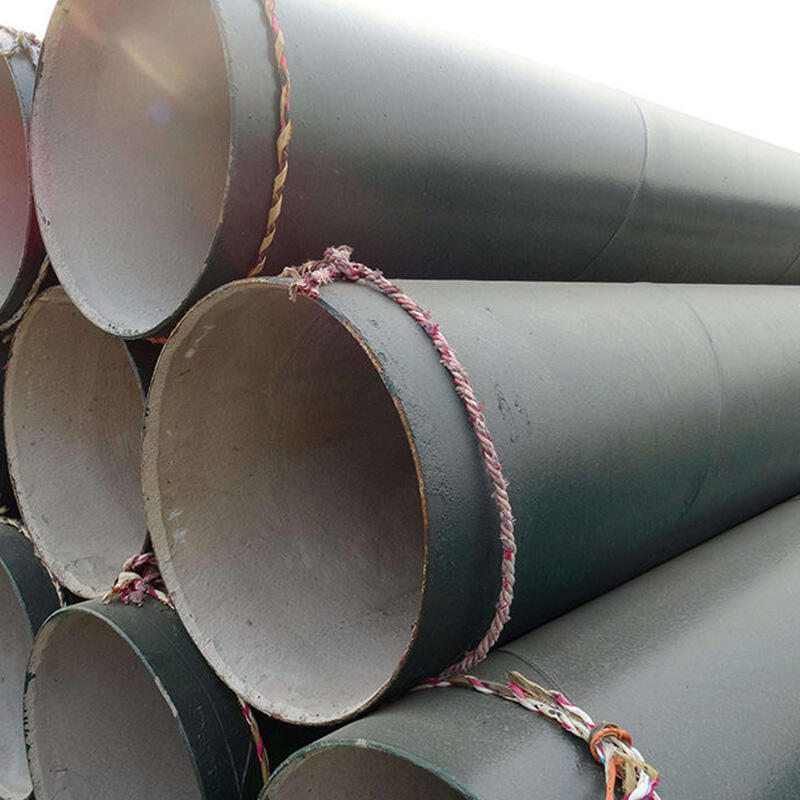

SSAW spiral steel pipe is a special type of welded steel pipe because the specific shape requires not only high-quality raw materials (such as seamless Doming tube), but also considerable expense in the processing technology. This makes ssaw particularly important for use in pipelines destined to carry essential fluids such slurry, water etc., formed within mines underground during the mining process gain access into uprights and subsequently hoisted out of mine shaft wells. spiral locking process and super-long welded lengths mean perfect thickness consistency, allowing the line to handle abrasive materials often present in mining applications. Pipelines help extract resources by efficiently transporting materials to processing facilities while, at the same time, saving energy and eliminating spills (70% of mineral slurry pipelines) which adds up having sustainable profits for mining operations as a whole.

How SSAW Pipe Technology Affects the Energy Industry in Australia

However, the installation of extensive SSAW for slurry applications is facilitating Australian mines to do more than just move earth; it employs a smoother material extraction process as 161 pipes made by steel suppliers are tough yet able to contour with difficult stretches. This enables the production of pipes from 350mm-7500mm in a range of wall thicknesses, resulting in bespoke solutions to meet individual mine requirements, for optimal flow rates and pressure management. SSAW pipes also feature added corrosion resistant coatings further extending life whilst reducing maintenance downtime and overall operational expenses, a key factor in the competitive Australian mining sector.

Championing SSAW Spiral Steel Pipes in infrastructure Building

Mining areas requiring construction of infrastructure have to be able to withstand the tough climate characteristics in Australia along with its rugged terrain. SSAW spiral steel pipes work well in this environment and are key components for the construction of bridges as struts, retaining walls and in drainage systems. Because they are inherently strong and ductile materials, they can be used where earthquakes frequently take place to assure the long-term stability of mining infrastructure. SSAW pipes in addition to being cheaper when compared with concrete or seamless pipes, help you save a great deal of cash especially for large mining shows without compromising on top quality and sustainability.

AN EXAMINATION INTO THE RESILIENCE OF SSAW PIPES IN AUSTRALIA'S HOSTILE MINING ENVIRONMENTS

The mining conditions found in Australia are amongst the most severe, with high temperatures, caustic soils and abrasive materials. In other words, as this blog will explore, they simply can withstand the weather better with their strong welds and additional coatings that you do not get on ERW steel pipes. The spirally welded steel pipes using a double-sided submerged arc welding process have many advantages in terms of cost and performance, but due to the inherent high-temperature discrete heat source characteristics that are widely used for welding straight seam steels, these paradoxes The manufacturing technology bottlenecks gradually highlight opening. This endurance results in fewer maintenance cycles and longer service life, highlighting why SSAW pipes are strategically crucial to keep mining activities running non-stop.

SSAW spiral steel pipes have inspired Australian mining innovation

SSAW spiral steel pipes playing pivotal role in sustainable application of the mining industry In Australia, a leading player as per updated regulations on technology adoption requirements. They contribute to the efficiency and safety of modern mining operations by providing a safe transportation system for resources, help rebuilding critical infrastructure. In addition to this, steel is recyclable to a high amount which supports the environmental aspirations of the sector and contributes towards global sustainability goals. The ongoing evolution of SSAW pipe technology will no doubt also have a significant part to play in upholding the competitiveness and environmental accountability on the global stage, as mining companies pursue strategic operational excellence into the future.

Finally, On Australian Mining should SSAW spiral steel pipe What impact?

Australian mining operations have further recognized the value of SSAW spiral steel pipes as an important asset. Being indispensable in bolstering the extraction process, reinforcing infrastructure and spirit of this growing sector through their flexibility, resilience to harsh environs. This continued dependency on high performance pipes as operations in Australia continue to develop confirms the strength of their claim as an enabler for success within mines both today and tomorrow.

Table of Contents

- The Importance of SSAW Spiral Steel Pipes for Australian Mining Sites

- Where SSAW Spiral Steel Pipes Are Key in Mining Australia

- How SSAW Pipe Technology Affects the Energy Industry in Australia

- Championing SSAW Spiral Steel Pipes in infrastructure Building

- AN EXAMINATION INTO THE RESILIENCE OF SSAW PIPES IN AUSTRALIA'S HOSTILE MINING ENVIRONMENTS

- SSAW spiral steel pipes have inspired Australian mining innovation

- Finally, On Australian Mining should SSAW spiral steel pipe What impact?

EN

EN