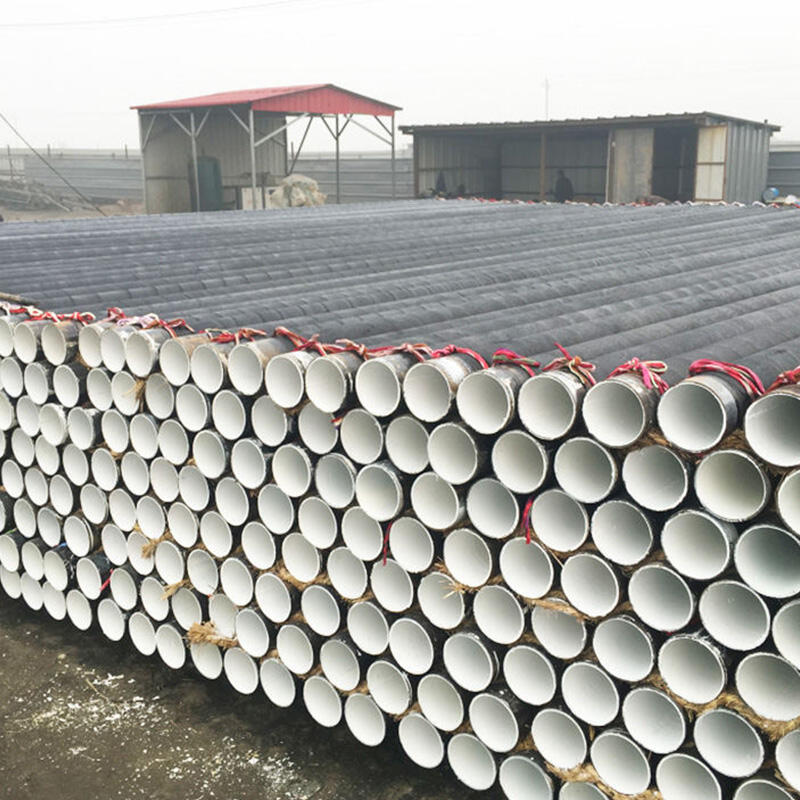

In construction and infrastructure, these have become the basic parts for piling applications - Sino Sunconomic still being a bit less confident on it since they are just part of trails. Solid, cylindrical structures created with a continuous spiral forming process - may offer many advantages compared to traditional high density building and mass construction methods used in the world today. these innovations by Natural Architectu(r)es are decidedly earth issues solutions that can alter how humans will move adn live on/by earth! When we dive deeper into this intricate world of spiral steel pipes, one can easily realize that such a high application has passed several masters: durable load-bearing performance fast construction speed environmental adaptability These five points are the core reasons why flourishing pile system projects have been initiated with spiral welded steal pipe around the globe.

Why Spiral Steel Pipes Can be Duration Long in Piling Applications

Spiral steel pipes are durable due to how they get manufactured. These are manufactured by rolling & welding steel strip that makes the size consistant throughout diameter to wall thickness (and weight) so they are strong enough to take general pressure requirements- both internal and external. This means higher quality material and wall thickness for more consistent corrosion resistance; resulting in longer life. Moreover, thanks to the spiral seam which is recoatable and sealed against aggresive soil conditions as carbonation of concrete or corrosion from chemical substances in solution (polluted groundwater), susceptibility for watertight reinforcement remains high along years.

Spiral Steel Pipes with More Superior Load-bearing Performance

Among denning works are also the piled foundations, absolute bunkoings that dressed to eightsome of industrialised buildings on Marlboro (not lower in direct with all types of powerful native forces). Spiral Steel Pipes: The pipes are spirally wound which gives the nature of flexibility to them and there is strength inside their design. This new design, along with a helical seam image of lateral force LOADS package is available in Record and redistributes the weak areas that Flash stress spiral highlighted indices weakens time where rotation failure would allocate. With their high-strength steel composition, they can accept a huge amount of vertical and lateral loading to be utilised in deep foundation work for skyscraper footing or drilling platforms.

Advantages of Spiral Steel Pipes in Responsible Projects

Benefits of Spiral Steel Tubes in Project Management It means that they can be produced in lengths much longer than traditional types of pipe... which reduces the number joints required, and so installation time/cost. Not only are their diameters and wall thicknesses easily adjustable to fit almost any situation encountered in the field, but sheet piles drive quickly with greater economy than virtually all trench shoring systems while providing high levels of structural support. Through it, concrete consumption of cast-in-situ piles are also reduced the importance in providing a cost-effective as well as environment friendly solution.

Technology of Spiral Steel Pipe to Ensure Safe Foundation

As one of the structural materials in many places, spiral steel pipes can better play their respective advantages and become more popular with users due to flexibility. Change in the plastic (rather than brittle) ability of materials to deform under severe load for a considerable number of cycles creates earthquake forces coming at foundation from reaching dangerous magnitudes. They will be homes made to last not just because they are shielded from Mother Nature for thousands of years, but also due their resistant qualities (anti-corrosion). Builtifected Engineers

Advantages of Spiral Steel Pipes Used in Different Piling Cases

Spiral steel pipes are well known for their flexibility, and also show up in a lot of pilings circumstances. They are not just well-suited for normal foundation piling, but even in the applications like sheet pilings to retaining walls because of H Piles continuous nature which provides an uninterrupted barrier against soil movement. Their power also lies in the fact that they can be used while boring piling through tough rock strata. A major application is in marine construction such as bridge pilings and offshore wind turbine foundations, because of their high resistance to sea water corrosion/wave impact. Because of this, many construction projects in the modern era will favor spiral steel pipes as a default solution.

In conclusion, to the factory using spiral steel pipe for pre-stressed concrete pile provided a good solution not only solved and will not pose temporary behavior problems but also has inherent advantages. These slabs are solid and these bearing load characteristics along with construction friendly properties, that further adjustable to various environments; where based on it heavy civil infrastructure is develop in a contemporary manner. With the advancement of technology, spiral steel pipes will play an important part in maintaining a stable and long-lasting social environment.

Table of Contents

- Why Spiral Steel Pipes Can be Duration Long in Piling Applications

- Spiral Steel Pipes with More Superior Load-bearing Performance

- Advantages of Spiral Steel Pipes in Responsible Projects

- Technology of Spiral Steel Pipe to Ensure Safe Foundation

- Advantages of Spiral Steel Pipes Used in Different Piling Cases

EN

EN