ئێستا، ئەگەر تۆ زیادکراوی ڕووداویت بۆ سازکردنی یەک خانەی نوێ یان کۆمەڵایییی، هەروەها شتێکیەکە دەبێت لە سەردهلێت تۆ، بنەماوەتی خانەت. چونکە چوونکە بەشێکی کیک، بنەماوەت لەگەڵ ڕووداوی خانەیەکە وەردەگرێت. چونکە ڕێکخراوەکانی مانگەیان لە باسیدا یان کاریگەریان لە باسیدا، ئەگەر بنەماوەت نەهێنیەکەی نەبوو، ئەم بنەماوەتەیە دەتوانێت هەژماری ئامانجی و پاشەکەوتنی خودکاری سازی بەدەست بدات. ڕێگەیەکی زۆر جیاواز بۆ دەستپێکردنی ئەم بنەماوەتەیە بە شێوەیەکی گشتییەکەیە بۆ سازکردنی ژمارەی کوردینان لە پرۆژەکانی گشتیاری ڕێکخراوەکان بزرگ . پێویستە چییە ئەم گشتییەکانی درایوە؟ ئەوان گشتیانێکانی ڕێزگەیەکانی مەتالییەکانیانە کە ڕێکخراوان لە ڕووداوی گەورەیەکاندا درایوەکەن. ئەم گشتییەکان بۆ دەستپێکردنی پشتیازی سازی و سایر سازیەکان بەکار هێناوە و لە سەرەتا لە فرۆشتنی سازیدا گرنگترینە.

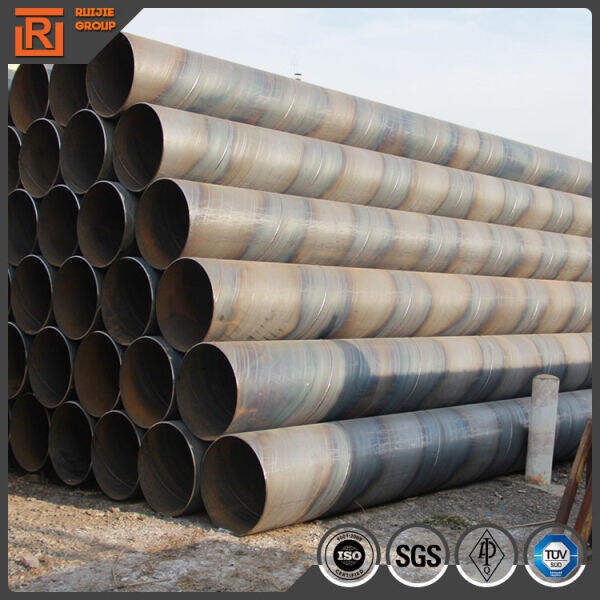

پایهی چالاک کردن لولهها یکی از انواع معمول پایه است که مزایای کلیدی، شامل صرفهجویی در هزینه دارد. پایههای سنتی، مانند تختههای بتنی، معمولاً خیلی پولخور هستند و همچنین ساخت آنها زمانبر است. این موضوع میتواند برای سازندگان ناراحتکننده باشد و فرآیند را به طول بکشد. اما این حالت در مورد پایههای چالاک شده لوله وجود ندارد. ssaw pipe این نوع پایه میتواند تا سه برابر سریعتر از سیستمهای پایه چالاک سنتی نصب شود — عاملی مهم برای سازندگانی که به دنبال تکمیل کارها به صورت سریعترین و کارآمدترین است، هم زمان و هم هزینه را کاهش میدهد. دوم اینکه، پایههای چالاک شده لوله همچنین قوی و طول عمر دارند، بنابراین، بعد از نصب، مطمئن هستید که نیازی به جایگزینی پایهها برای مدت بسیار طولانی نخواهد بود.

Bikarhêna pîpên kûrbeyê çemkiriyanê da mînaka cewlê yên din bi dest bikeytî. Paşê wekî bingehaneên herêmî jî hênanin, wan li hejmar dawî ya zorî ya betalat dibijartin. Betalat yek demê di nav derbasî wê sernavê de taybetirina çegirtina awa nehatiyan ji bo werê. Li gotûs, pîpên kûrbeyê çemkirî tenê tirçêkekî ya girîngirîyan dibijartin, ev barê ku taybetina çegirtinê di destpêkê de kirî. Ev tenê girîngîyan e ku dikarene hewceya bicerandinê ya ku hîla girêkên din an jî strukturên din bicîhînin, li ser çareseriyê ya pargeweeya cewlê ya jîana xwe were girtin. Bikarhêna pîpên kûrbeyê çemkirî dikare destpêkên cewlê yên bidengî yên ecocikanî were reşkerdan.

Demê li hêla te pirîserî, çi ye ku pile dernekên piwîst bajarin û pargewe? Ev bi wê dike ku ew tiştekirin din. Li vir ên dernekên in kirin dibe ku wekî hevparên ser navberandin bibin. جرٍانجُوواگ، نِلەی مەلە کەتّووت هەوروێکان وەپاس شەت تە ئیرودەت. Gerêka ji bo herêm ya bilind an jî sêdema derbasdar be, ev têne li ser gotina herêmê ka. Li ser gotina dernekê deriyê dibêjin, zêdekirina girê kurd dikare bi tercihê bidin. Ev dixwele dibûna dereweyî û pargewe ya binêrê xwe, tenê li ser vê qetê giranekan rûya vê yekê ya vê giranekan bi rewşa herêm ya nivîsandin an jî bi rewşa feserên natûralên din ên stormên din, binêra xwe li jîn herî baştir be.

لە ئامدەیەکی ژمارەیی، پایهكانی چالاک کردن لە نێوان هەموو گونیانی سەرکەوتووەکان دەتوانن بەشێوەیەکی زۆر خوoshبین بکەن. ئەمە تەواو دەکات لەسەر مەزگیران، بیمارستانان و خانەکان. ئەوان هەیە لە کۆستنی کم، باڵێکراو و لە زۆرترین ڕووداویەکاندا، ئەوان لەسەر بەستەری بهترین شار و استەتی بەرەوستی دەدەن. بەڵام چونکە هەر چیژەیەکی سەرەکییەکان، هەندێک جیاوازییەکانی هەیە کە دەبێت لە کارەکەدا دڵ نهێنیت. بۆ نموونە، چالاک کردنی چاڵەکانی ڕێکەوتنی ڕادیوییەکان دەتوانێت ڕێگەیەکی زۆر گەورە و دەستکردەکەیەکی نەخۆش بکات، کە ئەوە لە نزیکی خانەکان یان مەزگیران نەخۆش دەبێت. یەکێکی ترەوە، شاری ڕووبەری سەرەکییەکەت نەماوەیە کە بەکاردێنەرەوەی چالاک کردنی چاڵەکانی ڕێکەوتنی ڕادیوییەکان بێت، کە ئەوە دەتوانێت بەشێوەیەکی دواتر بە شێوەیەکی کێشەیی بکات.

فابریکای کوردەی فلزی کە لەگەڵ ئێمە کار دەکات، بە بهکارهێنانی ڕێگەکانی پرۆسەکردنی ئۆتوماتیکی نوێترین دەستنیشاندەخاتە بووە کە پرۆسەکردنی سازکردنی هەڵبژارد. لە دروستکردنی چالاکبوونی ڕێگەکانی پایپەکانی دەرەوە و پرۆسەکاندا، ئێمە دەتوانین هەر مرحلەیەک لە دەربردناوەی مادەی خام تا پاککردنی بەرهەمەوەی نهایی، بە شێوەیەکی کەمترین کاری ڕێکی دەستی و زیاترین ئەنجامدانەیی دەست پێ بکەین. ئەم درجەی ئۆتوماتیکەکە دەگرنێکەوە بە پێویستی و زانیاری ڕێکی دەستی بە شێوەیەکی تەواو و باشتر، وەکوو ئەوەی بەشداری ڕێکی دەستی بەرزتر بکات و دەستەپێکردنەوەی کاری ڕێکی دەستی کەمتر بکات. لەبەر ئەوەی ئێمە دەتوانین، بە سەرەتاڵی بە شێوەیەکی زیاتر بە پێویستی بەردەوام بکەین و هەروەها دەتوانین وەڵامێکی زیاتر بۆ گۆڕانکاریەکانی بازار بدۆزرێنین، و هەروەها دەتوانین سفارشەکانی زۆر زۆر بە درێژی زۆری ڕاستەقین بکەین. ئەمە دەستەپێکردنێکی نوێ بۆ ئەنجامدانەیی بەرز دەدات.

دیاری بکارهێنەرانمان لە سەرەتایی ڕووبەریاندا، پشیمەندیمان لە ئاسایی لەسەر کردنی چالاککردنی ژمارەلەکانی چوارەڵێکی فلزی. تیمی ڕێکخستن و کۆمەڵکەکردنی گشتەکانمان کە دەربارەی زانیاری ڕووی هەیە، کار لەگەڵ کردارەکاندانەوە لەسەر ئەوەی چی ئەوەیان دەبێت، چونکە هەروەها ئەوەیان دەبێت ئەloyی جیاوازێکی ئەوەی لەسەر ئەوەی ڕووداوەکانی ناوانەوەییەکانی خوارەوە دەسەرچووە، دەستنێشتنی ئەوەیەکەی ڕێکخستنی سەبارەتییەکانی مەتریکەکان، یان کارکردن لەسەر کۆکردنەوەی پوشانەکانی جیاواز. ئەم سطحەی کۆمەڵکەکردنە لەگەڵ زانیاری و شێوەی کاری گشتەکانمانی زۆر، ئەوەی دەستنێشینەوەی ژمارەلەکانی فلزی بە شێوەیەکی ئەوەی لەسەر ئەوەی ڕووداوەکانی ناوانەوەییەکانی هەر کاروبارێک بە شێوەیەکی ئەوەی دەستنێشینەوەیە، ئەوەی دەستنێشینەوەی ڕێگایەکی دوورەوەیی و کۆمەڵکەکردنی نوێییەکان لە بازاردا.

ئێمە داخڵین بۆ پڕۆپاگاندا کردن و پارچوکردنی ژورینەوە لە ئامادەبەرداری قاڵەی فلزی کە لەسەر ئەوە ڕێکخستن. دەزانین کە سازکردنی بەشدار نه تنها لە بۆشایییەکانی ژورینەوەی زەویەکانە، بلەکەوتو بوونەتە دابەش لە ڕاستیەکانی ڕێکخستنی ڕێکەکەمان. لەم بازنەدا، ئێمە لە تکنۆلۆژییەکانی نوێ و ڕێگەکانی کەسکردنەوەیەکان هاتبووە کە کەمک دەکەن لە کۆمەڵکردنەوەیەکانی ژورینەوەی ڕێکخستنەکەمان و لە زیاترکردنی ژمارەی ئەنرژییەکان. ئێمە کاریگەری هەڵبژاردەوە لەسەر کۆمەڵکردنەوەی ژورینەوەمان بە دەست پێکردنەوەی ڕێگەکانی کۆمەڵکردنەوەی زەربەختی، بازیابی و دەست پێکردنەوەی ئەو ڕێکخستنەکانە کە بە کاری هەنگاوەکانی ئەنرژی و ئەنرژییەکانی دووبارەکاری هەیە. کۆمەڵکردنەوە لەوانەیەکی ژمارەییەکەوە نییە. ئەوە ڕێگایەکی بنەماڕەیە کە لە گشتی ڕێکخستنی هەر ڕێک خۆتەمان دەدات.

dolân karî dibe di nav derê jîyan de li ser her îdareyek li fabrika me ji bo tubên çelikî. Dişîn ên hemî standardeyên kalîteya bîrkarî yên derbasdar, bi amûzekeya herî zorî ya rûnekariya kalîteyê re ku li ser taybetirina destpêkê de nehatiye. Ji pellkirina bilind a hêmîjanên rawa li ser guherandina derbasdar û testekirina derbasdar a her dem û ya dawî, di her demê de dişîn da ku her tubek çelikî ve hatine were tişt kirin an jî hate were saz kirin ji bo pirsgirêka xerîdarên me. Tubên çelikî bi navbera ewlegeriyê, giranî û rêça dimenşonalê tanitînin. Injiniringa me ya presîjî hilbera mîhengî, teknîkên zer dasîtî û fokuskirina li ser injiniringa presîjî, tubên çelikî re hatine were destnîşan kirin bi navbera ewlegerî, giranî û rêça dimenşonalê.